Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

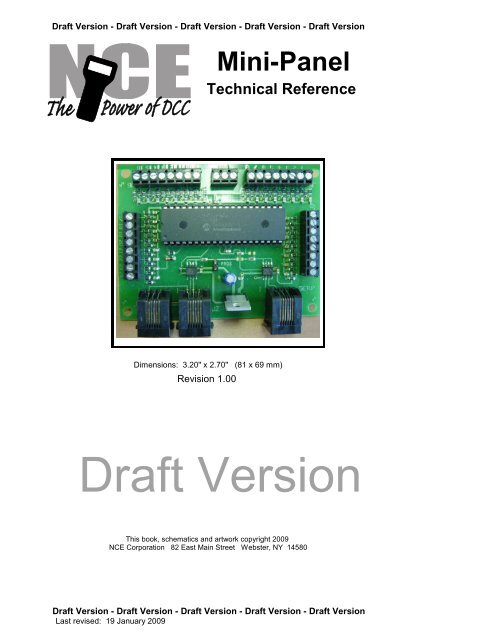

<strong>Mini</strong>-<strong>Panel</strong><br />

<strong>Technical</strong> <strong>Reference</strong><br />

Dimensions: 3.20" x 2.70" (81 x 69 mm)<br />

Revision 1.00<br />

Draft Version<br />

This book, schematics and artwork copyright 2009<br />

NCE Corporation 82 East Main Street Webster, NY 14580<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Description of <strong>Mini</strong>-<strong>Panel</strong><br />

The mini-panel is primarily intended to make it easy to build control panels for yards,<br />

towns, interlockings and other layout applications. A secondary use of the panel is to<br />

provide rudimentary automation of trains or control of signals. For more complex<br />

automation or signal operation the Macro-panel has more comprehensive<br />

implementation of these secondary features and more memory for command storage.<br />

The mini panel has 30 inputs that can be connected to pushbuttons, toggle switches,<br />

block detectors, etc. for the purpose of issuing accessory, macro or locomotive control<br />

commands. A thirty-first input is provided to act as a panel reset. Activation of an<br />

input can initiate sending a string of DCC commands through the track to turnouts,<br />

locomotives, signals or other DCC controlled devices. Inputs are activated by<br />

connecting them to the mini panel “GROUND”. This makes the mini panel compatible<br />

with all pushbutton/toggle switches and most block detectors.<br />

The mini-panel communicates with the command station via the cab bus and uses one<br />

cab bus address.<br />

Setup (programming) of the mini-panel is accomplished by plugging a ProCab or NCE<br />

USB adapter into the “setup” jack. If USB is used the mini-panel memory is accessed<br />

via binary CV read and write commands (page or direct mode). USB jumpers should<br />

be set for PowerCab v1.28 or ALL SYS. CV7 and CV8 return the manufacturer<br />

number and version of the <strong>Mini</strong> <strong>Panel</strong> as with a decoder when used with the USB<br />

interface.<br />

Installation Notes:<br />

The mini panel runs off Cab Bus power (nominal 12V DC) and draws about 90mA of<br />

current, slightly less than a ProCab. NOTE: When used with the PowerCab use the<br />

mini panel default address of 3.<br />

Wiring:<br />

See the diagram below for sample wiring ideas.<br />

Plug in ProCab<br />

or USB interface<br />

for setup<br />

Push<br />

Button<br />

Push<br />

Button<br />

25 26 27 28 29 30 31 GND<br />

SETUP CAB BUS<br />

PIN 1<br />

1 2 3 4 5 6 7 8 GROUND 9 10 11 12 13 14 15 16<br />

1 2 3 4<br />

17 18 19 20 21 22 23 24<br />

BD20<br />

Block Detector<br />

Cab Bus<br />

can be<br />

daisy chained<br />

through the<br />

<strong>Mini</strong>-<strong>Panel</strong><br />

Toggle<br />

Switch<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 2

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

<strong>Mini</strong> <strong>Panel</strong> Configuration Memory<br />

Location 0 - Cab bus address<br />

This is the Cab bus address useed by the <strong>Mini</strong>-<strong>Panel</strong> on the NCE Cab bus. The defualt<br />

address is 3. Setting this address to 0 will reset the <strong>Mini</strong>-<strong>Panel</strong> to factory defaults.<br />

Location 1 - Debounce timer<br />

Normally doesn't need to be changed. The value in this location determines how many<br />

cab bus "pings" (how many times the mini-panel is addressed on the cab bus) that an<br />

input must be grounded before the <strong>Mini</strong>-<strong>Panel</strong> recognizes it as a valid signal.<br />

Location 2 - For mat for display of unknown commands<br />

Memory location 2 controls whether (or not) the mini panel will display "unknown"<br />

commands in hex or decimal. A zero in location 2 means display in decimal, 1=hex.<br />

When using the USB interface (or the SETUP CONFIG menu) it is possible that<br />

command can get entered that the mini panel Review feature does not know how to<br />

display. In this case the mini panel will display the contents of these memory locations<br />

on the ProCab LCD screen as numeric values.<br />

Location 3 - Continuous Memory<br />

You can write fairly long automation sequences by constructing strings of 3 commands<br />

followed by a link to another string. This is inefficient in that only three out of four<br />

command locations in memory actually control anything.<br />

Memory location 3 can be programmed with an input number above which memory will<br />

be considered continuous. This means above that input number commands will<br />

continue to flow across each four command boundary and be executed until a<br />

terminating command of 0x00,0x00 is encountered.<br />

Remember that if any of those higher number inputs are grounded the associated<br />

commands starting at that input number will still be executed (unless memory location<br />

4 is programmed) and run until a termination command is encountered.<br />

Location 4 - Disabled inputs<br />

Memory location 4 can be programmed with the input number above which electrical<br />

status of those inputs will be ignored. Grounding one of those inputs will not result in<br />

execution of its command string. The input will still be used by the WAIT and SKIP<br />

commands that look at input status.<br />

Location 5 - Interrupting Wait Commands<br />

Wait commands will loop until the input condition is met. No other operations of the<br />

mini panel will be performed while waiting so the panel will appear dead. It is quite<br />

possible that situations on the layout will occur that upset the flow of your automation<br />

‘program’. Imagine that the program is waiting for a loco to get to a certain block and a<br />

derailment occurs causing the train to stop. The loco is replaced on the track but on a<br />

parallel track resulting in the loco never getting to the block that the program is<br />

expecting to be occupied. The mini panel will wait forever appearing to be<br />

unresponsive. You can utilize an unused input of the mini-panel as an ‘interrupt’ to<br />

break the mini panel out of this wait forever loop and continue normal operations.<br />

Program memory location 5 with the input number you want to use as the interrupt. By<br />

connection a pushbutton to this input you can provide a recovery mechanism without<br />

resetting the entire panel, losing turnout positions, signal aspects or loco function<br />

states.<br />

Location 6 -<br />

Memory location 6 is unused.<br />

Location 7 -<br />

Memory location 7 is unused.<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 3

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

To set up the <strong>Mini</strong> <strong>Panel</strong> plug a ProCab into the "SETUP" jack of the <strong>Mini</strong> <strong>Panel</strong>, make<br />

sure the Cab Bus is connected from the <strong>Mini</strong> <strong>Panel</strong> to the NCE DCC system and turn<br />

the power for the system on.<br />

The mini panel will detect the presence of the ProCab and you should see an opening<br />

LCD display of:<br />

NCE NCE MINI-PANEL<br />

MINI-PANEL<br />

VERSION VERSION 1.00<br />

1.00<br />

Press ENTER on the ProCab to get the main display for panel setup<br />

1=SETUP 2=MACRO<br />

3=TEST OPERATION<br />

We want to setup the panel so press "1" to enter setup mode, this will present the<br />

display screen as below<br />

Press "1" to setup an INPUT.<br />

SETUP MINI PANEL<br />

1=INPUT 2=CONFIG<br />

SETUP INPUT MENU<br />

INPUT NUMBER: 01<br />

We will start programming the inputs with input number 1. Type “1” followed by<br />

“ENTER” to program input number 1<br />

SETUP INPUT MENU<br />

STEP NUMBER: 1<br />

Normally when setting up an input we start with step number 1. We want to start<br />

programming at step 1 so just press ENTER to accept that step. Commands will be<br />

sent from the <strong>Mini</strong> <strong>Panel</strong> in order of their step number until an ‘empty’ step is<br />

encountered or four steps are completed.<br />

INP: 01 STEP: 1<br />

1=ACCY 2=MACRO<br />

At this point we’re ready to tell the mini panel exactly which command to send when<br />

button 1 is pushed. Press “1” to send an accessory command.<br />

INP: 01 STEP: 1<br />

ACCY NUMBER:<br />

Type the accessory number “1” followed by “ENTER”. Allowable NMRA accessory<br />

addresses are 1-2044. Accessory number 2044 is the broadcast address for<br />

accessories. There is no accessory address 0.<br />

INP: 01 STEP: 1<br />

1=NORM 2=REV<br />

Press “1” to send the accessory command for Normal when button 1 is pressed.<br />

INP: 01 STEP: 2<br />

1=ACCY 2=MACRO<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 4

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Note that the step number has increased to 2 indicating the last command has been<br />

accepted and the <strong>Mini</strong> <strong>Panel</strong> is ready for the next command for this input. We don’t<br />

need any more commands for this input so press “PROG/ESC” to return to the main<br />

menu.<br />

1=SETUP 2=MACRO<br />

3=TEST OPERATION<br />

Let’s review the command that has just been programmed. Press “2” to review.<br />

1=SETUP 2=REVIEW<br />

REVIEW INPUT:<br />

Type “1” and press “ENTER” to review the command sent by input number 1<br />

INP: 01 STEP: 1<br />

ACCY: 001 NORM<br />

The LCD no displays the accessory number (1) that we entered and the turnout<br />

position (Normal). Press “ENTER” to see the next step for this input<br />

INP: 01 STEP: 2<br />

--END--<br />

The display now indicates that there are no more entries programmed into this string.<br />

At this point you may continue pressing “ENTER” to cycle up through all the commands<br />

programmed if you wish. The Input and step numbers will be displayed as well as a<br />

description of the command for that step. Press “PROG/ESC” to return to the main<br />

menu.<br />

1=SETUP 2=MACRO<br />

3=TEST OPERATION<br />

At this point we have programmed and reviewed the command(s) that will be sent<br />

when input number 1 is grounded. The command can be tested by pressing “3”.<br />

TESTING<br />

INPUT NUMBER: 01<br />

Press “1” followed by “ENTER” to test input 1. The command string associated with<br />

input number 1 will be sent.<br />

1=SETUP 2=MACRO<br />

3=TEST OPERATION<br />

Putting the <strong>Mini</strong> <strong>Panel</strong> into test mode will also allow testing of any input by grounding<br />

that input number. Pressing any button on the ProCab will return the <strong>Mini</strong> <strong>Panel</strong> to<br />

setup mode.<br />

Finishing programing:<br />

At this point we have programmed, reviewed and tested the command(s) that will be<br />

sent when input number 1 is grounded. In a similar manner we can program the<br />

commands for inputs 2,3 and 4 using the proper accessory or macro commands.<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 5

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

MAIN MENU<br />

MENU NAVIGATION CHART<br />

2 3<br />

REVIEW<br />

TEST<br />

1<br />

SETUP<br />

2<br />

SETUP CONFIG INPUT #<br />

INPUT #<br />

1<br />

SETUP INPUT<br />

CAB ADDRESS<br />

INPUT #<br />

MEM ADDRESS<br />

STEP #<br />

MEMORY DATA<br />

5<br />

OTHER<br />

4<br />

SIGNAL<br />

3<br />

LOCO<br />

2<br />

MACRO<br />

1<br />

ACCY<br />

SIGNAL #<br />

MACRO #<br />

ACCY #<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 6<br />

ASPECT<br />

3<br />

FUNCTIONS<br />

2<br />

SPEED<br />

1<br />

SELECT<br />

NORM or REV<br />

LOCO #<br />

2<br />

F5-F8<br />

1<br />

F0-F4<br />

2<br />

28 MODE<br />

1<br />

128 MODE<br />

SPEED VAL<br />

SPEED VAL<br />

DIRECTION<br />

DIRECTION<br />

6<br />

SKIP<br />

5<br />

ADD NOP<br />

4<br />

OPS PROG LOC<br />

3<br />

LINK<br />

2<br />

WAIT<br />

1<br />

DELAYS<br />

CV #<br />

INPUT #<br />

2<br />

OPEN<br />

1<br />

GROUND<br />

2<br />

OPEN<br />

1<br />

GROUND<br />

2<br />

1/4 SECs<br />

1<br />

4 SECs<br />

DATA<br />

INPUT #<br />

INPUT #<br />

# #

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Command Descriptions:<br />

The following commands can be setup through the ProCab user interface and sent by<br />

the <strong>Mini</strong> <strong>Panel</strong>:<br />

Accessory/Macro commands<br />

� Accessory Command - all NMRA standard accessory addresses (1-2044) can be<br />

sent via the accessory command. There is no address 0. Address 2044 is the<br />

boradcast addresss.<br />

� Macro command - all NCE macro numbers (0-255) can be sent via the Macro<br />

command.<br />

Locomotive commands<br />

Speed and functions may be controlled<br />

� Select loco - A locomotive must be selected before any commands can be sent to<br />

that loco. Any NMRA standard locomotive address (up to 9999) may be selected.<br />

Short addresses fro 1-127 and long addresses 0-9999 are all valid and are entered<br />

in the same manner as they are selected in normal operations with a Pro/Power<br />

Cab. A leading zero before and address in the range of 1-127 indicates a long<br />

address. Once a loco address is selected all speed, function and Ops programing<br />

commands will be sent to that address unless another address is selected.<br />

� Speed commands - Both 28 and 128 speed mode commands can be sent. Once<br />

the speed is entered the direction can be changed by pushing the “DIRECTION”<br />

button.<br />

� Function commands - Function commands for F0-F8 can be sent. Due to the way<br />

the NMRA has defined function operation, functions are not controlled individually<br />

but are controlled in groups of four or five (or eight) at once. The state of F0-F4<br />

(function group 1) must be sent as one command while the state of F5-F8 (function<br />

group 2) is as a different command. When you choose the ‘Function’ option from<br />

the Loco commands Menu you must choose which function group you want to<br />

control<br />

ENTER FUNC GROUP<br />

1=F0-F4 2=F5-F8<br />

Once the group is selected you can select which functions in that group are to be<br />

on or off.<br />

PRESS F NUMBER<br />

DIGITS 0-4:-----<br />

In the case of function group 1 (LCD display above) pressing a digit of 0-4 will<br />

toggle that function on/off. If a digit is displayed the function will be on of a<br />

dash (“-”) is displayed the function will be off.<br />

PRESS F NUMBER<br />

DIGITS 0-4:0-23-<br />

In the display above F0 (headlight),F2 and F3 will be on and F1, F4 will be off.<br />

Signal commands<br />

� Signal Command - all NMRA standard signal addresses (1-2044) can be controlled<br />

via the signal command. Aspects are limited to the first 8 aspects (0-7). The<br />

signal commands are the NMRA standard signal commands using NMRA standard<br />

signal control packets. There is no address 0. Address 2044 is the broadcast<br />

address.<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 7

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Other commands<br />

There are 6 groups of ‘other’ commands executed by the <strong>Mini</strong> <strong>Panel</strong>. These<br />

commands do not result in a DCC command being sent but control the flow of the<br />

commands from the <strong>Mini</strong> <strong>Panel</strong>.<br />

� Delays - Two different delay commands can be used. These commands will cause<br />

the <strong>Mini</strong> <strong>Panel</strong> to delay execution of the next command in increments of ¼ second<br />

(up to 64 seconds total delay) or increments of 4 seconds (up to 1020 seconds<br />

total delay). A delay of 0 will cause the next command to be executed immediately.<br />

Use of this command causes all operation of the <strong>Mini</strong> <strong>Panel</strong> to stop while the<br />

command is in progress.<br />

� Wait - There are two Wait commands, one command waits for a indicated input to<br />

be grounded, the other waits for the indicated input to become ungrounded (open).<br />

Use of this command causes all operation of the <strong>Mini</strong> <strong>Panel</strong> to stop while the<br />

command is in progress.<br />

� Link - Use of this command will transfer operation to the string of four commands<br />

associated with another input.<br />

� Skip -There are two commands that can be used to make a decision based on the<br />

status of an input. These commands check the status of a user indicated input<br />

and either execute the next command in the string or skip over that command and<br />

execute the following command. One skip command skips if the indicated input is<br />

grounded the other skips if the input is ungrounded (open). These are very<br />

powerful commands allowing the <strong>Mini</strong> <strong>Panel</strong> to execute different commands based<br />

on the state of an input at the time the skip command is executed.<br />

� Nop - The No-Operation command. This command can be used as a place holder<br />

for future commands. When the <strong>Mini</strong> panel encounters this command in the<br />

command string it will be ignored and the next command will be executed.<br />

� CV Program - Allows programming of locomotive CVs in Ops mode. OPs mode<br />

programming requires 3 steps:<br />

set loco address (long or short)<br />

set CV number<br />

set CV data<br />

When the data command is executed an Ops programming command will be<br />

issued out over the cab bus to the track.<br />

<strong>Technical</strong> stuff:<br />

Linking command strings<br />

Inputs cannot normally be “decoupled” from their command string. If you link to the<br />

command string of an input that is connected to something that may activate that input,<br />

the commands for that input will be executed when the input is grounded. In some<br />

circumstances this may be desirable allowing portions of larger, longer command<br />

strings to be used. Normally you will want to leave linked inputs electrically<br />

unconnected.<br />

OPs programming command<br />

OPs mode programming requires 3 steps:<br />

set loco address (long or short)<br />

set CV number<br />

set CV data<br />

When the data is set the programming command will be issued out over the cab bus to<br />

the track. If the loco address has already been set in a previous command that<br />

address will be used. The same applies to the CV number. You can use this to your<br />

advantage to program momentum using the (3 required steps) into a locomotive then<br />

later just programming a new momentum value using only the set CV data command.<br />

Command string terminator<br />

When the mini panel encounters the command 0x00,0x00 it is considered the<br />

command string terminator. Any commands following the terminator in the string will<br />

not be executed.<br />

Input scanning<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 8

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

The inputs of the <strong>Mini</strong>-panel are scanned in numerical order. Inputs are sampled in<br />

groups of 8 and stored in temporary memory. This group is then scanned for active<br />

inputs. An input at or near ground potential is considered active. When an input is<br />

transitions from open (high due to 5v pull-up resistor) to ground (low) it will trigger<br />

execution of a string of up to four commands associated with that input. Transitions<br />

from low to high are ignored and no action is performed.<br />

The lowest numbered active input of the group of eight is acted upon first. The<br />

command string associated with that input will be executed. Execution of the<br />

command string will continue until a command of 0x00,0x00 is encountered or until 4<br />

commands are executed.<br />

One exception to the four command limit is the “link” command that transfers execution<br />

to another input command string. This allows borrowing the memory location from<br />

other (possibly) unused inputs to create longer strings of commands. The memory<br />

space for the unused input can be used by another command string.<br />

Once a command string has completed execution the next active input will be located<br />

and its command string executed.<br />

After a group of 8 inputs is scanned and any active inputs are serviced the next group<br />

of 8 inputs will be sampled.<br />

Inputs are captured eight at a time and actions generated by those 8 inputs are<br />

completed before capturing the next higher group of eight. If an input of one group of 8<br />

initiates a long string of commands (see linking below) that will take a significant period<br />

of time is it possible to miss momentarily activated inputs. This is not a problem for<br />

typical applications with quick acting command strings such those used with a control<br />

panel that just issues accessory/macro commands. The problem may occur in layout<br />

automation applications that require long periods of time waiting for a loco to enter a<br />

block or delays used for stopping at a station. In these cases you must carefulyl<br />

consider the series of event that may be happening and how commands are strung<br />

together.<br />

USB interface<br />

When using the NCE USB interface memory locations 1-255 can be read or written<br />

using programming track direct mode binary commands 0xa8 and 0xa9. It is<br />

necessary to put the USB interface into program track mode with the 0x9e command<br />

before attempting programming other wise you will just get the “not in program track<br />

mode” response from the USB interface. This will allow you to test the commands you<br />

just programmed without having to disconnect the USB interface. You cannot read<br />

memory location 0 (Cab Bus address). Memory locations 6 (ver) and 7 (mfr) allow<br />

you to determine the <strong>Mini</strong> <strong>Panel</strong> manufacturer and software version. <strong>Mini</strong> panel<br />

software versions start at 200 (decimal) and the manufacturer is 11 decimal (NCE).<br />

You may still write memory locations 6 and 7 but not read them through the USB<br />

interface. They are trapped by the mini panel software when the USB is used for<br />

reading with the manufacturer and version substituted for the actual values in memory.<br />

You can read them by plugging a ProCab into the SETUP port.<br />

When using Decoder Pro for programming select:<br />

Service mode programming<br />

Comprehensive Programmer format<br />

NMRA<br />

Raw CVs 1-255<br />

Click on “READ” for CV1. Due to multiple layers of buffering between the USB and<br />

<strong>Mini</strong> <strong>Panel</strong> the first CV read will fail but you should get valid reads and writes from that<br />

point on. Using Direct Byte mode is slightly faster than Paged mode.<br />

When finished programming you can put the <strong>Mini</strong> <strong>Panel</strong> back into operational mode<br />

with the 0xa6 (Write register) command. Any register and value is OK. The panel is<br />

just looking for any Write Register command<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 9

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Gotchas<br />

� Any and all commands for Input 31 will be executed before the mini panel tries to<br />

detect a ProCab plugged into the SETUP port. If you have an automation program<br />

that begins at power up the ProCab will not be detected for setup until the program<br />

completes. If the program doesn’t complete (“wait forever” etc) you will not be able<br />

to access the setup menus. Workaround: You can force the <strong>Mini</strong> <strong>Panel</strong> into setup<br />

mode by installing the “PROG” jumper. It is best to remove the jumper as soon as<br />

you get into setup mode as the jumper shorts out the mini panel internal Cab Bus<br />

receive line. The mini panel chips should be protected against this short but it’s best<br />

to not tempt fate.<br />

�<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 10

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Command format of the <strong>Mini</strong> <strong>Panel</strong><br />

The table below describes the hex bytes stored in the memory locations for each command<br />

Hex 1st Byte 2nd Byte Command<br />

0x00 0000 0000 0000 0000 command string terminator - stop<br />

execution<br />

00->07 0000 0aaa aaaa aaaa accessory on(N) 1->2044, addr 0 not<br />

valid<br />

08->0f 0000 1aaa aaaa aaaa accessory off(R) 1->2044, addr 0 not<br />

valid<br />

40->7f 01nn naaa aaaa aaaa signal 1-2044 aspect 0-7, addr 0 not<br />

valid<br />

80->b7 10aa aaaa aaaa aaaa set long loco address 0-10239<br />

b8-bb 1011 10nn nnnn nnnn set OPs CV num. 1-1024 (set loco/accy<br />

addr 1st)<br />

bc 1011 1100 dddd dddd set OPs loco CV data (set CV number<br />

first)<br />

bd 1011 1101 dddd dddd set OPs accy CV data (set CV number<br />

first)<br />

be 1011 1110 dddd dddd set OPs signal CV data (set CV number<br />

first)<br />

bf 1011 1111 nnnn nnnn delay in 4 second increments<br />

c0 1100 0000 0sss ssss stored loco 128 speed reverse<br />

c0 1100 0000 1sss ssss stored loco 128 speed forward<br />

c1 1100 0001 000s ssss stored loco 28 speed reverse (0-28<br />

valid)<br />

c1 1100 0001 001s ssss stored loco 28 speed forward (0-28<br />

valid)<br />

c1 1100 0001 010f ffff function group 1 f0,f4,f3,f2,f1<br />

c1 1100 0001 0110 ffff function group 2 f8,f7,f6,f5<br />

c1 1100 0001 0111 ffff function group 3 f12,f11,f10,f9<br />

c1 1100 0001 1aaa aaaa set short loco address<br />

c2 1100 0010 ffff ffff f20->f13<br />

c3 1100 0011 ffff ffff f28->f21<br />

c4 1100 0011 nnnn nnnn loco detected in block 0-255<br />

c5 1100 0101 nnnn nnnn delay in 1/4 second increments<br />

c6 1100 0110 000n nnnn wait until input nnnnn active, 0 not<br />

valid<br />

c6 1100 0110 001n nnnn wait until input nnnnn not active, 0<br />

not valid<br />

c6 1100 0110 010n nnnn link to execute commands for input<br />

nnnnn<br />

c6 1100 0110 011x xxxx unused<br />

c6 1100 0110 100n nnnn if input nnnnn active skip the next<br />

command<br />

c6 1100 0110 101n nnnn if input nnnnn not active skip the<br />

next command<br />

c6 1100 0110 11xx xxxx not used<br />

c7 1100 0111 nnnn nnnn macro 0-255<br />

c8-cf 1100 1aaa aaaa aaaa set accessory/signal address 1-2044<br />

d0-fe ---- ---- ---- ---- unused<br />

ff<br />

Key:<br />

1111 1111 1111 1111 nop - no-operation, just execute next<br />

command<br />

a - address bit, f - function bit, n - number, s - speed data, x - undefined<br />

Notes:<br />

Commands bf and c5 block reading/execution of all inputs until time expires<br />

The wait commands of c6 block reading of all other inputs until condition is met<br />

The “skip” commands of c6 work in “real time” (right now) and do not wait or block other<br />

commands<br />

Once the loco address is set all subsequent locomotive commands will be sent to that address.<br />

Once the accy or signal address is set all subsequent OPs programming commands will be sent<br />

to that address<br />

Due to memory limitations the 0xbd,0xbe,0xc2, 0xc3, 0xc8 and 0xc6 function group 3<br />

commands are not available through the ProCab setup interface. They are available for use<br />

through the USB interface.<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 11

Chart of <strong>Mini</strong> <strong>Panel</strong> memory locations<br />

4<br />

15<br />

7e/7f<br />

126/127<br />

3<br />

15<br />

7c/7d<br />

124/125<br />

2<br />

15<br />

7a/7b<br />

122/123<br />

1<br />

15<br />

78/79<br />

120/121<br />

4<br />

31<br />

fe/ff<br />

254/255<br />

4<br />

14<br />

76/77<br />

118/119<br />

3<br />

31<br />

fc/fd<br />

252/253<br />

3<br />

14<br />

74/75<br />

116/117<br />

2<br />

31<br />

fa/fb<br />

250/251<br />

2<br />

14<br />

72/73<br />

114/115<br />

1<br />

31<br />

f8/f9<br />

248/249<br />

1<br />

14<br />

70/71<br />

112/113<br />

4<br />

30<br />

f6/f7<br />

246/247<br />

4<br />

13<br />

6e/6f<br />

110/111<br />

3<br />

30<br />

f4/f5<br />

244/245<br />

3<br />

13<br />

6c/6d<br />

108/109<br />

2<br />

30<br />

f2/f3<br />

242/243<br />

2<br />

13<br />

6a/6b<br />

106/107<br />

1<br />

30<br />

f0/f1<br />

240/241<br />

1<br />

13<br />

68/69<br />

104/105<br />

4<br />

30<br />

ee/ef<br />

238/239<br />

4<br />

12<br />

66/67<br />

102/103<br />

3<br />

29<br />

ec/ed<br />

236/237<br />

3<br />

12<br />

64/65<br />

100/101<br />

2<br />

29<br />

ea/eb<br />

234/235<br />

2<br />

12<br />

62/63<br />

98/99<br />

1<br />

29<br />

e8/e9<br />

232/233<br />

1<br />

12<br />

60/61<br />

96/97<br />

4<br />

29<br />

e6/e7<br />

230/231<br />

4<br />

11<br />

5e/5f<br />

94/95<br />

3<br />

28<br />

e4/e5<br />

228/229<br />

3<br />

11<br />

5c/5d<br />

92/93<br />

2<br />

28<br />

e2/e3<br />

226/227<br />

2<br />

11<br />

5a/5b<br />

90/91<br />

1<br />

28<br />

e0/e1<br />

224/225<br />

1<br />

11<br />

58/59<br />

88/89<br />

4<br />

27<br />

de/df<br />

222/223<br />

4<br />

10<br />

56/57<br />

86/87<br />

3<br />

27<br />

dc/dd<br />

220/221<br />

3<br />

10<br />

54/55<br />

84/85<br />

2<br />

27<br />

da/db<br />

218/219<br />

2<br />

10<br />

52/53<br />

82/83<br />

1<br />

27<br />

d8/d9<br />

216/217<br />

1<br />

10<br />

50/51<br />

80/81<br />

4<br />

26<br />

d6/d7<br />

214/215<br />

4<br />

9<br />

4e/4f<br />

78/79<br />

3<br />

26<br />

d4/d5<br />

212/213<br />

3<br />

9<br />

4c/4d<br />

76/77<br />

2<br />

26<br />

d2/d3<br />

210/211<br />

2<br />

9<br />

4a/4b<br />

74/75<br />

1<br />

26<br />

d0/d1<br />

208/209<br />

1<br />

9<br />

48/49<br />

72/73<br />

4<br />

25<br />

ce/cf<br />

206/207<br />

4<br />

8<br />

46/47<br />

70/71<br />

3<br />

25<br />

cc/cd<br />

204/205<br />

3<br />

8<br />

44/45<br />

68/69<br />

2<br />

25<br />

ca/cb<br />

202/203<br />

2<br />

8<br />

42/43<br />

66/67<br />

1<br />

25<br />

c8/c9<br />

200/201<br />

1<br />

8<br />

40/41<br />

64/65<br />

4<br />

24<br />

c6/c7<br />

198/199<br />

4<br />

7<br />

3e/3f<br />

62/63<br />

3<br />

24<br />

c4/c5<br />

196/197<br />

3<br />

7<br />

3c/3d<br />

60/61<br />

2<br />

24<br />

c2/c3<br />

194/195<br />

2<br />

7<br />

3a/3b<br />

58/59<br />

1<br />

24<br />

c0/c1<br />

192/193<br />

1<br />

7<br />

38/39<br />

56/57<br />

4<br />

23<br />

be/bf<br />

190/191<br />

4<br />

6<br />

36/37<br />

54/55<br />

3<br />

23<br />

bc/bd<br />

188/189<br />

3<br />

6<br />

34/35<br />

52/53<br />

2<br />

23<br />

ba/bb<br />

186/187<br />

2<br />

6<br />

32/33<br />

50/51<br />

1<br />

23<br />

b8/b9<br />

184/185<br />

1<br />

6<br />

30/31<br />

48/49<br />

4<br />

22<br />

b6/b7<br />

182/183<br />

4<br />

5<br />

2e/2f<br />

46/47<br />

3<br />

22<br />

b4/b5<br />

180/181<br />

3<br />

5<br />

2c/2d<br />

44/45<br />

2<br />

22<br />

b2/b3<br />

178/179<br />

2<br />

5<br />

2a/2b<br />

42/43<br />

1<br />

22<br />

b0/b1<br />

176/177<br />

1<br />

5<br />

28/29<br />

40/41<br />

4<br />

21<br />

ae/af<br />

174/175<br />

4<br />

4<br />

26/27<br />

38/39<br />

3<br />

21<br />

ac/ad<br />

172/173<br />

3<br />

4<br />

24/25<br />

36/37<br />

2<br />

21<br />

aa/ab<br />

170/171<br />

2<br />

4<br />

22/23<br />

34/35<br />

1<br />

21<br />

a8/a9<br />

168/169<br />

1<br />

4<br />

20/21<br />

32/33<br />

4<br />

20<br />

a6/a7<br />

166/167<br />

4<br />

3<br />

1e/1f<br />

30/31<br />

3<br />

20<br />

a4/a5<br />

164/165<br />

3<br />

3<br />

1c/1d<br />

28/29<br />

2<br />

20<br />

a2/a3<br />

162/163<br />

2<br />

3<br />

1a/1b<br />

26/27<br />

1<br />

20<br />

a0/a1<br />

160/161<br />

1<br />

3<br />

18/19<br />

24/25<br />

4<br />

19<br />

9e/9f<br />

158/159<br />

4<br />

2<br />

16/17<br />

22/23<br />

3<br />

19<br />

9c/9d<br />

156/157<br />

3<br />

2<br />

14/15<br />

20/21<br />

2<br />

19<br />

9a/9b<br />

154/155<br />

2<br />

2<br />

12/13<br />

18/19<br />

1<br />

19<br />

98/99<br />

152/153<br />

1<br />

2<br />

10/11<br />

16/17<br />

4<br />

18<br />

96/97<br />

150/151<br />

4<br />

1<br />

0e/0f<br />

14/15<br />

3<br />

18<br />

94/95<br />

148/149<br />

3<br />

1<br />

0c/0d<br />

12/13<br />

2<br />

18<br />

92/93<br />

146/147<br />

2<br />

1<br />

0a/0b<br />

10/11<br />

1<br />

18<br />

90/91<br />

144/145<br />

1<br />

1<br />

08/09<br />

8/9<br />

4<br />

17<br />

8e/8f<br />

142/143<br />

---<br />

0x07<br />

7<br />

3<br />

17<br />

8c/8d<br />

140/141<br />

---<br />

0x06<br />

6<br />

2<br />

17<br />

8a/8b<br />

138/139<br />

“Wait” Interrupt<br />

0x05<br />

5<br />

1<br />

17<br />

88/89<br />

136/137<br />

Dead inputs<br />

0x04<br />

4<br />

4<br />

16<br />

86/87<br />

134/135<br />

Continuous mem<br />

0x03<br />

3<br />

3<br />

16<br />

84/85<br />

132/133<br />

Clear 8 mem loc<br />

0x02<br />

2<br />

2<br />

16<br />

82/83<br />

130/131<br />

Debounce<br />

0x01<br />

1<br />

1<br />

16<br />

80/81<br />

128/129<br />

Cab Bus Addr<br />

0x00<br />

0<br />

Step #<br />

INP #<br />

Hex<br />

Decimal<br />

Step #<br />

INP #<br />

Hex<br />

Decimal<br />

Description<br />

Memory location<br />

Description<br />

Memory location<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 12

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Default values for memory locations<br />

Location 0 - 3 Cab bus address, 2-63 are OK<br />

Location 1 - 5 Debounce timer (normally doesn’t ever need change)<br />

Location 2 - 0 Clear all 8 memory locations for an input when programming 1=don’t<br />

Location 3 - 0 Input number at/above which command string memory is continuous<br />

Location 4 - 0 Input number at/above which commands will not execute if input active<br />

Location 5 - 0 Input number than can be used to interrupt “wait” commands<br />

Location 6 - Unused (Software version 201 when read via USB - CV7)<br />

Location 7 - Unused (Manufacturer 11 when read via USB - CV8)<br />

Locations 8 through 255 - 0<br />

Warning: This product contains chemicals known to the State of<br />

California to cause cancer, birth defects or other reproductive harm.<br />

Warranty<br />

This product is fully factory tested and warranted against manufacturing defects for a<br />

period of 1 year. As the circumstances under which this product is installed can not be<br />

controlled, failure due to installation problems can not be warranted. This includes<br />

misuse, miswiring, operation under loads or voltages beyond the design range of the<br />

product.<br />

For warranty or non-warranty repair/replacement send the product (an any payment, if<br />

required) to:<br />

NCE Warranty Center 82 East Main St. Webster, New York 14580<br />

The terms Silent Running, Power Pro, PowerCab , ProCab, Switch-It the NCE logo with “Power of DCC” slogan are trademarks of<br />

NCE Corporation. The distinctive shape of the ProCab when used with a thumbwheel speed control and LCD display is a<br />

trademark of NCE Corporation.<br />

Draft Version - Draft Version - Draft Version - Draft Version - Draft Version<br />

Last revised: 19 January 2009 Page 13