Test Specification for Eurobalise FFFIS

Test Specification for Eurobalise FFFIS

Test Specification for Eurobalise FFFIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

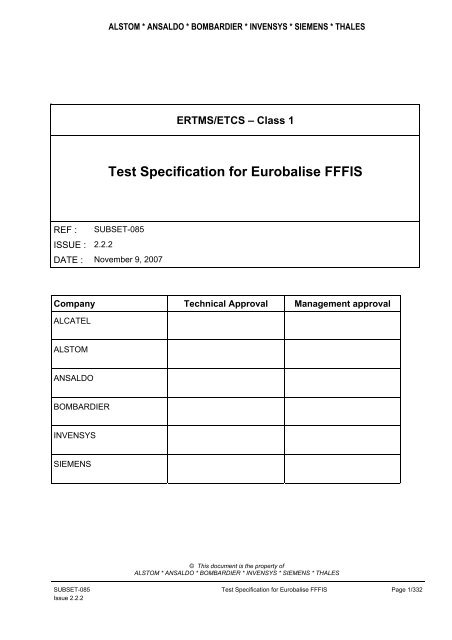

ALSTOM * ANSALDO * BOMBARDIER * INVENSYS * SIEMENS * THALES<br />

ERTMS/ETCS – Class 1<br />

<strong>Test</strong> <strong>Specification</strong> <strong>for</strong> <strong>Eurobalise</strong> <strong>FFFIS</strong><br />

REF : SUBSET-085<br />

ISSUE : 2.2.2<br />

DATE : November 9, 2007<br />

Company Technical Approval Management approval<br />

ALCATEL<br />

ALSTOM<br />

ANSALDO<br />

BOMBARDIER<br />

INVENSYS<br />

SIEMENS<br />

© This document is the property of<br />

ALSTOM * ANSALDO * BOMBARDIER * INVENSYS * SIEMENS * THALES<br />

SUBSET-085<br />

Issue 2.2.2<br />

<strong>Test</strong> <strong>Specification</strong> <strong>for</strong> <strong>Eurobalise</strong> <strong>FFFIS</strong> Page 1/332

Page 2 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

Foreword<br />

This Norm incorporates results from the original work (“<strong>Eurobalise</strong> FFFS”) carried out by the EUROSIG Consortium<br />

1 under the financial support of the European Commission (<strong>Eurobalise</strong>/Euroloop Project -’92/94’,<br />

ERTMS/Eurosig Project -‘95/98’, and EMSET Project -‘96/00’), and in close co-operation with technical bodies<br />

of the UIC 2 and of the EEIG ERTMS User Group 3 . The EUROSIG specifications were subsequently updated<br />

by the UNISIG Consortium 4 in consideration of further technical work in development and test areas.<br />

The main body of Part 2 of this Norm, and the relevant Annexes designated as “normative”, constitute the mandatory<br />

requirements <strong>for</strong> test methods and tools <strong>for</strong> verification of compliance with the mandatory requirements<br />

of Part 1. Annexes designated as “in<strong>for</strong>mative”, either provide background in<strong>for</strong>mation, or outline nonmandatory<br />

requirements and optional features.<br />

1<br />

2<br />

3<br />

4<br />

The EUROSIG Consortium was composed of the following European Companies working in the Railway Signalling<br />

area: ACEC Transport, Adtranz Signal, Alcatel SEL, GEC Alsthom Transport, Ansaldo Trasporti, CSEE Transport,<br />

SASIB Railway, Siemens, and Westinghouse Signal.<br />

UIC: Union Internationale de Chemins de Fer.<br />

EEIG ERTMS User Group: European Economic Interest Group was composed of some European Railways (DBAG, FS<br />

SpA, NS, RENFE, SNCF, BR) managing the implementation of ERTMS trial sites aimed at full functional verifications.<br />

The UNISIG Consortium was composed of the following European Companies working in the Railway Signalling area:<br />

Adtranz Signal, Alcatel, Alstom, Ansaldo Signal, Invensys Rail, and Siemens.

Page 3 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

Contents<br />

1 INTRODUCTION ________________________________________________________ 17<br />

1.1 Application Range __________________________________________________________17<br />

1.2 Scope_____________________________________________________________________17<br />

2 NORMATIVE REFERENCES _______________________________________________ 19<br />

3 TERMINOLOGY AND DEFINITIONS _________________________________________ 19<br />

3.1 Acronyms and Abbreviations_________________________________________________19<br />

3.2 Definitions ________________________________________________________________20<br />

3.3 Influence of Tolerances ______________________________________________________20<br />

4 TESTS OF THE UP-LINK BALISE____________________________________________ 21<br />

4.1 Reference <strong>Test</strong> Configurations________________________________________________21<br />

4.1.1 General ________________________________________________________________________21<br />

4.1.2 Monitored Interfaces ______________________________________________________________22<br />

4.1.3 <strong>Test</strong> Tools and Procedures__________________________________________________________22<br />

4.2 Laboratory <strong>Test</strong>s ___________________________________________________________23<br />

4.2.1 Generic <strong>Test</strong> and Calibration Set-up notes _____________________________________________23<br />

4.2.2 Up-link Field Con<strong>for</strong>mity __________________________________________________________25<br />

4.2.2.1 General ____________________________________________________________________25<br />

4.2.2.2 Calibration of 4.2 MHz Balise Loop Current in the Contact Zone_______________________26<br />

4.2.2.3 Balise Up-link Con<strong>for</strong>mity Measurements in the Contact Zone_________________________28<br />

4.2.2.4 Evaluation of Up-link Con<strong>for</strong>mity in the Contact Zone _______________________________30<br />

4.2.2.5 Calibration of 4.2 MHz Balise Loop Current in the Side Lobe Zone_____________________31<br />

4.2.2.6 Up-link Reference Field in the Side Lobe Zone _____________________________________31<br />

4.2.2.7 Balise Up-link Con<strong>for</strong>mity Measurements in the Side Lobe Zone_______________________31<br />

4.2.2.8 Evaluation of Up-link Con<strong>for</strong>mity in the Side Lobe Zone _____________________________32<br />

4.2.2.9 Calibration of 4.2 MHz Balise Loop Current in the Cross-talk Protected Zone_____________33<br />

4.2.2.10 Up-link Reference Field in the Cross-talk Protected Zone __________________________35<br />

4.2.2.11 Balise Up-link Con<strong>for</strong>mity Measurements in the Cross-talk Protected Zone ____________36<br />

4.2.2.12 Evaluation of Up-link Con<strong>for</strong>mity in the Cross-talk Protected Zone __________________37<br />

4.2.3 Tele-powering Field Con<strong>for</strong>mity_____________________________________________________38<br />

4.2.3.1 General ____________________________________________________________________38<br />

4.2.3.2 Calibration of 27 MHz Tele-powering flux in the Contact Zone ________________________39<br />

4.2.3.3 Balise Tele-powering Con<strong>for</strong>mity Measurements in Contact Zone ______________________42<br />

4.2.3.4 Evaluation of Tele-powering Con<strong>for</strong>mity in the Contact Zone _________________________44

Page 4 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.2.3.5 Calibration of 27 MHz Tele-powering flux in the Side Lobe Zone ______________________45<br />

4.2.3.6 Tele-powering Reference Field in the Side Lobe Zone _______________________________45<br />

4.2.3.7 Balise Tele-powering Con<strong>for</strong>mity Measurements in the Side Lobe Zone _________________46<br />

4.2.3.8 Evaluation of Tele-powering Con<strong>for</strong>mity in the Side Lobe Zone _______________________46<br />

4.2.4 I/O Characteristics________________________________________________________________47<br />

4.2.4.1 General ____________________________________________________________________47<br />

4.2.4.2 Calibration of 4.2 MHz <strong>for</strong> Balise Input to Output Characteristics ______________________48<br />

4.2.4.3 Balise Input to Output Characteristics Measurements ________________________________50<br />

4.2.4.4 Evaluation of I/O Characteristics ________________________________________________53<br />

4.2.5 Cross-talk Immunity with Cables ____________________________________________________54<br />

4.2.5.1 General ____________________________________________________________________54<br />

4.2.5.2 Calibration of 27 MHz Tele-powering flux ________________________________________54<br />

4.2.5.3 Calibration of Balise response __________________________________________________56<br />

4.2.5.4 Cross-talk Measurements ______________________________________________________59<br />

4.2.5.5 LZB Cable <strong>Test</strong>ing ___________________________________________________________62<br />

4.2.6 Balise Impedance_________________________________________________________________66<br />

4.2.6.1 General ____________________________________________________________________66<br />

4.2.6.2 <strong>Test</strong> Conditions______________________________________________________________67<br />

4.2.6.3 Calibration of 27 MHz Tele-powering flux ________________________________________68<br />

4.2.6.4 Balise Impedance Measurements ________________________________________________69<br />

4.2.7 Up-link Signal Characteristics_______________________________________________________71<br />

4.2.7.1 General ____________________________________________________________________71<br />

4.2.7.2 Nominal <strong>Test</strong> Conditions ______________________________________________________72<br />

4.2.7.3 Specific <strong>Test</strong> Conditions_______________________________________________________74<br />

4.2.7.4 Toggling AM <strong>Test</strong> Conditions __________________________________________________75<br />

4.2.7.5 Calibration of 27 MHz Tele-powering flux ________________________________________77<br />

4.2.7.6 <strong>Test</strong> of Centre Frequency and Frequency Deviation _________________________________79<br />

4.2.7.7 <strong>Test</strong> of Start-up after Side Lobe _________________________________________________80<br />

4.2.7.8 <strong>Test</strong> of Mean Data Rate _______________________________________________________80<br />

4.2.7.9 <strong>Test</strong> of MTIE (Maximum Time Interval Error) _____________________________________81<br />

4.2.7.10 <strong>Test</strong> of Amplitude Jitter during start-up ramp____________________________________81<br />

4.2.7.11 <strong>Test</strong> of Amplitude Jitter during steady state flux _________________________________82<br />

4.2.7.12 <strong>Test</strong> of Signal Bandwidth ___________________________________________________82<br />

4.2.7.13 <strong>Test</strong> of Delay Time and Balise controlling interface Parameter Variation ______________82<br />

4.2.7.14 <strong>Test</strong> of Compatibility ______________________________________________________83<br />

4.2.7.15 <strong>Test</strong> of Balise start with Toggling AM and steep Tele-powering slope ________________83<br />

4.2.7.16 <strong>Test</strong> Matrices_____________________________________________________________84

Page 5 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.2.8 Balise controlling interface per<strong>for</strong>mance measurements___________________________________88<br />

4.2.8.1 Introduction ________________________________________________________________88<br />

4.2.8.2 General <strong>Test</strong> Conditions _______________________________________________________88<br />

4.2.8.3 Electrical Data Requirements ___________________________________________________89<br />

4.2.8.4 Calibration of the 27 MHz Tele-powering flux _____________________________________94<br />

4.2.8.5 Functional <strong>Test</strong>s _____________________________________________________________96<br />

4.2.9 <strong>Test</strong> <strong>for</strong> damaging _______________________________________________________________108<br />

4.2.9.1 General ___________________________________________________________________108<br />

4.2.9.2 Calibration of Tele-powering flux level __________________________________________108<br />

4.2.9.3 <strong>Test</strong> Procedure, <strong>Test</strong> <strong>for</strong> damaging ______________________________________________108<br />

4.3 Requirements <strong>for</strong> <strong>Test</strong> Tools ________________________________________________108<br />

5 TESTS OF THE ON-BOARD EQUIPMENT_____________________________________ 109<br />

5.1 Reference <strong>Test</strong> Configurations_______________________________________________109<br />

5.1.1 General _______________________________________________________________________109<br />

5.1.2 Monitored Interfaces _____________________________________________________________109<br />

5.1.3 <strong>Test</strong> Tools and Procedures_________________________________________________________110<br />

5.2 Laboratory <strong>Test</strong>s __________________________________________________________111<br />

5.2.1 General _______________________________________________________________________111<br />

5.2.1.1 Introduction _______________________________________________________________111<br />

5.2.1.2 General <strong>Test</strong> Set-up _________________________________________________________112<br />

5.2.1.3 <strong>Test</strong> Set-up Notes ___________________________________________________________113<br />

5.2.2 <strong>Test</strong> Conditions _________________________________________________________________114<br />

5.2.2.1 Nominal Conditions _________________________________________________________114<br />

5.2.2.2 Specific Conditions__________________________________________________________116<br />

5.2.3 Evaluation of Radiation Pattern_____________________________________________________118<br />

5.2.3.1 General Description _________________________________________________________118<br />

5.2.3.2 <strong>Test</strong> Procedure, Evaluation of Radiation Pattern ___________________________________120<br />

5.2.4 Creation of Signal Pattern <strong>for</strong> Dynamic <strong>Test</strong>s__________________________________________122<br />

5.2.4.1 General Description _________________________________________________________122<br />

5.2.4.2 Example of Signal Pattern Generation ___________________________________________124<br />

5.2.4.3 Example of Algorithm <strong>for</strong> Signal Pattern Generation _______________________________126<br />

5.2.5 Transmission <strong>Test</strong>s ______________________________________________________________128<br />

5.2.5.1 General Description _________________________________________________________128<br />

5.2.5.2 <strong>Test</strong> Procedure, Transmission <strong>Test</strong>s _____________________________________________129<br />

5.2.5.3 Acceptance Criteria, Transmission <strong>Test</strong>s _________________________________________131<br />

5.2.6 Electrical Tele-powering Characteristics______________________________________________131<br />

5.2.6.1 General Description _________________________________________________________131

Page 6 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

5.2.6.2 <strong>Test</strong> Set-up <strong>for</strong> Tele-powering verification _______________________________________132<br />

5.2.6.3 <strong>Test</strong> Procedure, CW Mode ____________________________________________________133<br />

5.2.6.4 <strong>Test</strong> Procedure, Interoperable Mode_____________________________________________134<br />

5.2.6.5 Acceptance Criteria, Electrical Tele-powering Characteristics ________________________135<br />

5.2.7 Maximum Flux Level ____________________________________________________________135<br />

5.2.7.1 General Description _________________________________________________________135<br />

5.2.7.2 <strong>Test</strong> Set-up <strong>for</strong> Maximum Flux Level verification __________________________________136<br />

5.2.7.3 <strong>Test</strong> Procedure, Maximum Flux Level ___________________________________________137<br />

5.2.7.4 Acceptance Criteria, Maximum Flux Level _______________________________________137<br />

5.2.8 Electrical Up-link Signal Characteristics______________________________________________138<br />

5.2.8.1 General Description _________________________________________________________138<br />

5.2.8.2 <strong>Test</strong> Procedure, Electrical Up-link Characteristics__________________________________138<br />

5.2.8.3 <strong>Test</strong> Cases _________________________________________________________________139<br />

5.2.8.4 Acceptance Criteria, Electrical Up-link Characteristics ______________________________139<br />

5.2.9 Cross-talk Immunity _____________________________________________________________140<br />

5.2.9.1 General Description _________________________________________________________140<br />

5.2.9.2 <strong>Test</strong> Procedure, Cross-talk Immunity ____________________________________________141<br />

5.2.9.3 Acceptance Criteria, Cross-talk Immunity ________________________________________142<br />

5.2.10 Cross-talk Immunity with Cables _________________________________________________143<br />

5.2.10.1 General ________________________________________________________________143<br />

5.2.10.2 Cross-talk Measurements __________________________________________________144<br />

5.2.10.3 LZB Cable <strong>Test</strong>ing _______________________________________________________148<br />

5.2.11 Balise Detectability Supervision __________________________________________________151<br />

5.2.11.1 General Description ______________________________________________________151<br />

5.2.11.2 Acceptance Criteria, Balise Detectability Supervision ____________________________151<br />

5.2.12 Handling of various Telegrams___________________________________________________152<br />

5.2.12.1 General Description ______________________________________________________152<br />

5.2.12.2 <strong>Test</strong> Procedure, Handling of various Telegrams_________________________________152<br />

5.2.12.3 Acceptance Criteria, Handling of various Telegrams _____________________________152<br />

5.2.13 Handling of Balise Sequences____________________________________________________153<br />

5.2.13.1 General Description ______________________________________________________153<br />

5.2.13.2 <strong>Test</strong> Procedure, Handling of Balise Sequences__________________________________153<br />

5.2.13.3 Acceptance Criteria, Handling of Balise Sequences ______________________________153<br />

5.2.14 Fundamental concepts of Basic Receiver ___________________________________________154<br />

5.2.14.1 General Description ______________________________________________________154<br />

5.2.14.2 <strong>Test</strong> Procedure, Fundamental concepts of Basic Receiver _________________________154<br />

5.2.14.3 Acceptance Criteria, Fundamental concepts of Basic Receiver _____________________155

Page 7 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

5.3 Requirements <strong>for</strong> <strong>Test</strong> Tools ________________________________________________155<br />

ANNEX A (NORMATIVE), REFERENCE TEST TELEGRAMS _________________________ 156<br />

A1 GENERAL __________________________________________________________ 156<br />

A2 TEST TELEGRAMS ___________________________________________________ 157<br />

A3 SPECIFIC TEST TELEGRAMS ___________________________________________ 161<br />

ANNEX B (NORMATIVE), AIR-GAP REFERENCE EQUIPMENT _______________________ 163<br />

B1 GENERAL __________________________________________________________ 163<br />

B2 REFERENCE LOOPS __________________________________________________ 163<br />

B2.1 Size of Reference Loops __________________________________________________163<br />

B2.2 Field Requirements ______________________________________________________164<br />

B2.2.1 Magnetic Field (H-field) ________________________________________________________164<br />

B2.2.2 Electric Field (E-field) _________________________________________________________165<br />

B2.3 Compensation <strong>for</strong> the Impedance of the Reference Loop _______________________166<br />

B2.4 Frequency Characteristics of the Reference Field _____________________________167<br />

B2.5 Influence of Debris ______________________________________________________167<br />

B2.5.1 The flux through the Reference Area ______________________________________________167<br />

B2.5.2 The field from the Balise________________________________________________________167<br />

B2.6 Con<strong>for</strong>mity <strong>Test</strong>ing of Reference Loops _____________________________________168<br />

B2.6.1 <strong>Test</strong> Procedure________________________________________________________________168<br />

B2.6.2 Measurement set-up ___________________________________________________________169<br />

B2.6.3 Instrument set-up and Calibration_________________________________________________170<br />

B2.6.4 Compensation <strong>for</strong> the impedance of the Reference Loop _______________________________170<br />

B2.6.5 <strong>Test</strong> Environment _____________________________________________________________172<br />

B2.6.6 Calculation of correction factors__________________________________________________172<br />

B2.6.7 Labelling and Marking of Reference Loops _________________________________________174<br />

B2.7 Application <strong>for</strong> Reference Loop Calibration _________________________________175<br />

B2.7.1 General _____________________________________________________________________175<br />

B2.7.2 Standard Size Reference Loop ___________________________________________________176<br />

B2.7.3 Reduced Size Reference Loop ___________________________________________________180<br />

B3 TEST ANTENNA _____________________________________________________ 184<br />

B3.1 Size of the <strong>Test</strong> Antenna __________________________________________________184<br />

B3.2 Field Requirements ______________________________________________________184<br />

B3.3 Impedance _____________________________________________________________184

Page 8 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

B4 ACTIVATION ANTENNA _______________________________________________ 185<br />

B4.1 Size of the Activation Antenna _____________________________________________185<br />

B4.2 Field Requirements ______________________________________________________185<br />

B4.3 Impedance _____________________________________________________________185<br />

B5 CONDITIONS TO BE TESTED ____________________________________________ 185<br />

B5.1 General ________________________________________________________________185<br />

B5.2 Debris _________________________________________________________________186<br />

B5.2.1 General _____________________________________________________________________186<br />

B5.2.2 Liquid Debris ________________________________________________________________186<br />

B5.2.3 Non-liquid Debris _____________________________________________________________187<br />

B5.2.4 Reference Loop and Balise ______________________________________________________188<br />

B5.2.4.1 Salt Water ______________________________________________________________188<br />

B5.2.4.2 Clear Water _____________________________________________________________188<br />

B5.2.4.3 Iron Ore (Magnetite) ______________________________________________________188<br />

B5.2.4.4 Iron Ore (Hematite)_______________________________________________________188<br />

B5.2.4.5 Fresh Snow _____________________________________________________________188<br />

B5.2.4.6 Wet Snow ______________________________________________________________189<br />

B5.2.4.7 Ice ____________________________________________________________________189<br />

B5.2.4.8 Ballast _________________________________________________________________189<br />

B5.2.4.9 Dry Sand _______________________________________________________________189<br />

B5.2.4.10 Wet Sand _______________________________________________________________189<br />

B5.2.4.11 Mud without Salt Water ___________________________________________________189<br />

B5.2.4.12 Mud with Salt Water ______________________________________________________189<br />

B5.2.4.13 Iron Dust _______________________________________________________________190<br />

B5.2.4.14 Coal Dust_______________________________________________________________190<br />

B5.2.4.15 Oil and Grease___________________________________________________________190<br />

B5.2.5 Antenna _____________________________________________________________________190<br />

B5.2.5.1 Ice ____________________________________________________________________190<br />

B5.2.5.2 Fresh Snow _____________________________________________________________190<br />

B5.2.5.3 Wet Snow ______________________________________________________________190<br />

B5.2.5.4 Mud without Salt Water ___________________________________________________191<br />

B5.2.5.5 Mud with Salt Water ______________________________________________________191<br />

B5.2.5.6 Iron Ore (Magnetite) ______________________________________________________191<br />

B5.2.5.7 Iron Ore (Hematite)_______________________________________________________191<br />

B5.2.5.8 Iron Dust _______________________________________________________________191<br />

B5.2.5.9 Coal Dust_______________________________________________________________191

Page 9 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

B5.2.5.10 Oil and Grease___________________________________________________________191<br />

B5.3 Metallic Objects_________________________________________________________192<br />

B5.3.1 Iron Bars outside the metallic free volume of the Balise _______________________________192<br />

B5.3.2 Guard Rails __________________________________________________________________193<br />

B5.3.3 Metallic Plane underneath the Balise ______________________________________________194<br />

B5.3.4 Steel Sleepers ________________________________________________________________195<br />

B5.3.5 Other Sleepers________________________________________________________________196<br />

B5.3.6 Loop Cable __________________________________________________________________196<br />

B5.3.7 Metallic objects outside the metal free volume of the Antenna Unit ______________________197<br />

B5.3.8 Metallic Masses in the Track ____________________________________________________199<br />

ANNEX C (NORMATIVE), MEASUREMENT POINTS _______________________________ 200<br />

C1 GEOMETRICAL TEST POINTS CONTACT ZONE _____________________________ 200<br />

C2 GEOMETRICAL TEST POINTS SIDE LOBE ZONE ____________________________ 201<br />

C3 GEOMETRICAL TEST POINTS CROSS-TALK PROTECTED ZONE ________________ 202<br />

C4 TEST POINTS FOR CONTACT ZONE AND SIDE-LOBE ZONE_____________________ 203<br />

C5 TEST POINTS FOR CROSS-TALK PROTECTED ZONE__________________________ 204<br />

C6 TEST MATRIX FOR TRANSMISSION AND CROSS-TALK TESTS__________________ 205<br />

C6.1 <strong>Test</strong> Conditions versus <strong>Test</strong> Zones__________________________________________205<br />

C6.2 <strong>Test</strong> Conditions versus Geometrical <strong>Test</strong> Points ______________________________206<br />

C7 TEST MATRIX FOR OTHER CHARACTERISTICS ____________________________ 207<br />

C7.1 <strong>Test</strong> Conditions versus Characteristics ______________________________________207<br />

C7.2 <strong>Test</strong> Conditions versus Geometrical <strong>Test</strong> Points ______________________________208<br />

C7.3 Source of data <strong>for</strong> Controlled Balises versus <strong>Test</strong> Cases ________________________209<br />

ANNEX D (INFORMATIVE), DESCRIPTIONS OF TEST TOOLS ________________________ 210<br />

D1 DESCRIPTION OF TIME AND ODOMETER MODULE (LTOM) __________________ 210<br />

D1.1 Operational Context _____________________________________________________210<br />

D1.2 Functional requirements__________________________________________________211<br />

D1.2.1 Basic functions _______________________________________________________________211<br />

D1.2.2 Operational modes ____________________________________________________________211<br />

D1.2.2.1 General ________________________________________________________________211<br />

D1.2.2.2 Idle or static mode________________________________________________________211<br />

D1.2.2.3 Self-test mode ___________________________________________________________211

Page 10 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

D1.2.2.4 Dynamic simulated mode __________________________________________________212<br />

D1.2.2.5 Real dynamic mode_______________________________________________________212<br />

D1.3 External interfaces ______________________________________________________213<br />

D1.3.1 Interface T4__________________________________________________________________213<br />

D1.3.2 Man Machine Interface _________________________________________________________214<br />

D1.3.3 Interface V2__________________________________________________________________214<br />

D1.3.4 Interface V3__________________________________________________________________214<br />

D1.3.5 Interface V4__________________________________________________________________215<br />

D1.3.6 Interface S1 __________________________________________________________________215<br />

D1.3.7 Interface S2 __________________________________________________________________215<br />

D1.3.8 Interface S3 __________________________________________________________________215<br />

D1.3.9 Interface S4 __________________________________________________________________215<br />

D1.3.10 Interface S5________________________________________________________________216<br />

D1.4 Required per<strong>for</strong>mance ___________________________________________________216<br />

D2 DESCRIPTION OF REFERENCE SIGNAL GENERATOR (RSG) __________________ 217<br />

D2.1 Operational Context _____________________________________________________217<br />

D2.2 Functional requirements__________________________________________________218<br />

D2.2.1 Basic functions _______________________________________________________________218<br />

D2.2.1.1 General ________________________________________________________________218<br />

D2.2.1.2 RSG_1_________________________________________________________________219<br />

D2.2.1.3 RSG_2_________________________________________________________________220<br />

D2.2.1.4 RSG_C ________________________________________________________________220<br />

D2.2.2 Operational modes ____________________________________________________________221<br />

D2.2.2.1 RSG_1_________________________________________________________________221<br />

D2.2.2.2 RSG_2_________________________________________________________________221<br />

D2.2.2.3 RSG_C ________________________________________________________________222<br />

D2.3 External interfaces ______________________________________________________223<br />

D2.3.1 RSG_1______________________________________________________________________223<br />

D2.3.1.1 Interface with the LTMS___________________________________________________223<br />

D2.3.1.2 Interface with the LTOM __________________________________________________223<br />

D2.3.2 RSG_2______________________________________________________________________223<br />

D2.3.2.1 Interface with the LTMS___________________________________________________223<br />

D2.3.2.2 <strong>Test</strong> Antenna ____________________________________________________________223<br />

D2.3.2.3 Current Sense (CS) from <strong>Test</strong> Antenna________________________________________224<br />

D2.3.2.4 Interface with the LRRT ___________________________________________________224<br />

D2.3.3 RSG_C _____________________________________________________________________224<br />

D2.3.3.1 Interface with the LTMS___________________________________________________224

Page 11 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

D2.3.3.2 Interface with the LTOM __________________________________________________224<br />

D2.4 Required per<strong>for</strong>mance ___________________________________________________225<br />

D2.4.1 RSG_1______________________________________________________________________225<br />

D2.4.2 RSG_2______________________________________________________________________225<br />

D2.4.3 RSG_C _____________________________________________________________________227<br />

D3 DESCRIPTION OF ANTENNA POSITIONING TOOL (APT)______________________ 228<br />

D3.1 Operational Context _____________________________________________________228<br />

D3.2 Functional requirements__________________________________________________229<br />

D3.2.1 Basic functions _______________________________________________________________229<br />

D3.2.2 Operational modes ____________________________________________________________230<br />

D3.2.2.1 General ________________________________________________________________230<br />

D3.2.2.2 Idle mode_______________________________________________________________230<br />

D3.2.2.3 Self test mode ___________________________________________________________230<br />

D3.2.2.4 Recovery of the lost position________________________________________________230<br />

D3.2.2.5 Quasi static antenna positioning _____________________________________________231<br />

D3.2.2.6 Continuous longitudinal antenna movement____________________________________231<br />

D3.3 External interfaces ______________________________________________________232<br />

D3.3.1 Interface T2__________________________________________________________________232<br />

D3.3.2 Man Machine Interface _________________________________________________________232<br />

D3.3.3 Interface V3__________________________________________________________________233<br />

D3.4 Required per<strong>for</strong>mance ___________________________________________________233<br />

D3.4.1 <strong>Test</strong> bed characteristics _________________________________________________________233<br />

D3.4.2 Positioning Accuracy __________________________________________________________234<br />

D4 DESCRIPTION OF OFF-LINE TELEGRAM GENERATOR (OLTG)________________ 236<br />

D4.1 Operational Context _____________________________________________________236<br />

D4.2 Functional requirements__________________________________________________237<br />

D4.2.1 Basic functions _______________________________________________________________237<br />

D4.2.2 Functional architecture _________________________________________________________238<br />

D4.3 External Interfaces ______________________________________________________239<br />

D4.3.1 User Data____________________________________________________________________239<br />

D4.3.1.1 General ________________________________________________________________239<br />

D4.3.1.2 Packet and variables representation __________________________________________239<br />

D4.3.1.3 Hexadecimal representation ________________________________________________239<br />

D4.3.2 Telegram File ________________________________________________________________239<br />

D4.3.3 Printout _____________________________________________________________________239

Page 12 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

D5 DESCRIPTION OF TEST MANAGEMENT SYSTEM (LTMS) ____________________ 240<br />

D5.1 Operational Context _____________________________________________________240<br />

D5.2 Functional requirements__________________________________________________241<br />

D5.2.1 Basic Functions_______________________________________________________________241<br />

D5.2.2 Operational Modes ____________________________________________________________242<br />

D5.2.2.1 General ________________________________________________________________242<br />

D5.2.2.2 Idle and self-test mode ____________________________________________________242<br />

D5.2.2.3 <strong>Test</strong> procedure control_____________________________________________________243<br />

D5.3 External interfaces ______________________________________________________249<br />

D5.3.1 Man Machine Interface (MMI) ___________________________________________________249<br />

D5.3.2 Interface V1__________________________________________________________________250<br />

D5.3.3 Interface T1__________________________________________________________________250<br />

D5.3.4 Interface T2__________________________________________________________________250<br />

D5.3.5 Interface T3__________________________________________________________________250<br />

D5.3.6 Interface T4__________________________________________________________________250<br />

D5.3.7 Interface T5__________________________________________________________________250<br />

D5.3.8 Interface T6__________________________________________________________________250<br />

D5.3.9 Interface T7__________________________________________________________________251<br />

D5.4 Required per<strong>for</strong>mance ___________________________________________________251<br />

D6 DESCRIPTION OF REFERENCE RECEIVER TOOL (LRRT) ____________________ 252<br />

D6.1 Operational Context _____________________________________________________252<br />

D6.2 Functional requirements__________________________________________________253<br />

D6.2.1 Basic functions _______________________________________________________________253<br />

D6.2.2 Operational modes ____________________________________________________________254<br />

D6.2.2.1 Idle and self-test mode ____________________________________________________254<br />

D6.2.2.2 Up-link signal analysis (LRRT_1) ___________________________________________254<br />

D6.2.2.3 Tele-powering signal analysis (LRRT_2) ______________________________________258<br />

D6.2.2.4 Interface ‘C’ signal analysis (LRRT_C) _______________________________________260<br />

D6.3 External interfaces ______________________________________________________263<br />

D6.3.1 Interface T1__________________________________________________________________263<br />

D6.3.2 Fast trigger Interface S6 ________________________________________________________264<br />

D6.3.3 Man Machine Interface – MMI___________________________________________________264<br />

D6.4 Required per<strong>for</strong>mance ___________________________________________________265<br />

D6.4.1 LRRT_1 ____________________________________________________________________265<br />

D6.4.2 LRRT_2 ____________________________________________________________________265<br />

D6.4.3 LRRT_C ____________________________________________________________________265

Page 13 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

ANNEX E (INFORMATIVE), TEST INTERFACES FOR THE ON-BOARD EQUIPMENT _______ 266<br />

E1 INTERFACE V1 ______________________________________________________ 266<br />

E1.1 General ________________________________________________________________266<br />

E1.2 Operational Data ________________________________________________________266<br />

E1.2.1 Mode Selection (TESTCONF) ___________________________________________________266<br />

E1.2.2 Mode Status (BTMSTAT) ______________________________________________________267<br />

E1.2.3 Link Status (ALIVE)___________________________________________________________268<br />

E1.3 <strong>Test</strong> Data ______________________________________________________________268<br />

E1.3.1 Self-test Report (ANTTEST) ____________________________________________________268<br />

E1.3.2 Balise Passage Report (BALL_PASS) _____________________________________________269<br />

E2 INTERFACE V2 ______________________________________________________ 271<br />

E2.1 General ________________________________________________________________271<br />

E2.2 Interface V2 Data _______________________________________________________272<br />

E3 INTERFACE V4 ______________________________________________________ 273<br />

E3.1 General ________________________________________________________________273<br />

E3.2 Interface V4 Signals _____________________________________________________273<br />

E4 PHYSICAL AND LINK CONTROL_________________________________________ 274<br />

E4.1 Architecture ____________________________________________________________274<br />

E4.2 Physical Control ________________________________________________________275<br />

E4.2.1 General _____________________________________________________________________275<br />

E4.2.2 Interface ‘V 1 ’, Mechanical Data __________________________________________________275<br />

E4.2.3 Interface ‘V 2 ’, Mechanical Data __________________________________________________277<br />

E4.3 Link Control ___________________________________________________________279<br />

E4.3.1 General _____________________________________________________________________279<br />

E4.3.2 Interface ‘V 1 ’_________________________________________________________________279<br />

E4.3.3 Interface ‘V 2 ’_________________________________________________________________280<br />

E4.4 Interface ‘V 1 ’ Link Synchronisation ________________________________________281<br />

E4.4.1 General _____________________________________________________________________281<br />

E4.4.2 Case 1 – The BTM is switched on be<strong>for</strong>e the Interface ‘V 1 ’ driver _______________________281<br />

E4.4.3 Case 2 – The Interface ‘V 1 ’ driver is switched on be<strong>for</strong>e the BTM _______________________282<br />

E4.4.4 Case 3 – The Interface ‘V 1 ’ driver is re-started but the BTM remains on __________________283<br />

E4.4.5 Case 4 – The BTM is re-started but the Interface ‘V 1 ’ driver remains on __________________284<br />

E4.4.6 Behaviour of the Interface ‘V 1 ’ driver _____________________________________________285<br />

ANNEX F (INFORMATIVE), TEST TOOLS AND INSTRUMENTS _______________________ 287

Page 14 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

F1 RECOMMENDED TEST TOOLS AND INSTRUMENTS __________________________ 287<br />

F2 RECOMMENDED HIGH POWER LOW PASS FILTER__________________________ 289<br />

F2.1 CHARACTERISTICS_________________________________________________ 289<br />

F2.2 SUGGESTED IMPLEMENTATION _______________________________________ 290<br />

F2.3 INDUCTOR CHARACTERISTICS ________________________________________ 291<br />

F3 SPECIFIC LOW PASS FILTER CHARACTERISTICS ___________________________ 292<br />

ANNEX G (INFORMATIVE), RECOMMENDED TEST PROCEDURES ____________________ 293<br />

G1 TESTING OF LEU OUTPUT RETURN LOSS_________________________________ 293<br />

G1.1 <strong>Test</strong> Abstract ___________________________________________________________293<br />

G1.2 <strong>Test</strong> Set-up <strong>for</strong> Interface ‘C1’ _____________________________________________293<br />

G1.3 Calibration of the test set-up <strong>for</strong> Interface ‘C1’ _______________________________294<br />

G1.4 <strong>Test</strong> Procedure <strong>for</strong> Interface ‘C1’ __________________________________________294<br />

G1.5 <strong>Test</strong> Set-up <strong>for</strong> Interface ‘C6’ _____________________________________________295<br />

G1.6 Calibration of the test set-up <strong>for</strong> Interface ‘C6’ _______________________________296<br />

G1.7 <strong>Test</strong> Procedure <strong>for</strong> Interface ‘C6’ __________________________________________297<br />

G2 HARMONIC CONTENTS ON THE INTERFACE ‘C6’ LEU OUTPUT________________ 298<br />

ANNEX H (INFORMATIVE), AIR-GAP REFERENCE EQUIPMENT _____________________ 299<br />

H1 GENERAL __________________________________________________________ 299<br />

H2 REFERENCE LOOPS __________________________________________________ 299<br />

H2.1 Reference Loop Design ___________________________________________________299<br />

H2.1.1 Overall Design _______________________________________________________________299<br />

H2.1.2 Loop Structure Mechanics ______________________________________________________301<br />

H2.1.3 Non-conductive Joints__________________________________________________________302<br />

H2.1.4 Printed Circuit Board __________________________________________________________302<br />

H2.1.5 PCB Components _____________________________________________________________302<br />

H2.1.6 Encapsulation ________________________________________________________________303<br />

H2.2 Utilisation of the Reference Loops __________________________________________303<br />

H2.3 Tuning of the Reference Loops ____________________________________________304<br />

H2.4 Calibration of the Reference Loops _________________________________________305<br />

H3 TEST ANTENNAS ____________________________________________________ 306<br />

H3.1 General ________________________________________________________________306

Page 15 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

H3.2 <strong>Test</strong> Antenna Design _____________________________________________________307<br />

H3.2.1 Overall Design _______________________________________________________________307<br />

H3.2.2 Screen Plate__________________________________________________________________308<br />

H3.2.3 Holder ______________________________________________________________________308<br />

H3.2.4 Loops_______________________________________________________________________308<br />

H3.2.4.1 General ________________________________________________________________308<br />

H3.2.4.2 Capacitors ______________________________________________________________308<br />

H3.2.4.3 Printed Circuit Board (PCB) ________________________________________________309<br />

H3.2.4.4 27.095 MHz Trans<strong>for</strong>mer __________________________________________________309<br />

H3.2.4.5 Current Sense Trans<strong>for</strong>mer and Current Probe __________________________________309<br />

H3.2.4.6 4.23 MHz Trans<strong>for</strong>mer ____________________________________________________310<br />

H3.2.5 Balun _______________________________________________________________________310<br />

H3.3 Modified <strong>Test</strong> Antenna Design_____________________________________________310<br />

H3.4 Tuning of <strong>Test</strong> Antenna __________________________________________________310<br />

H3.5 Per<strong>for</strong>mance Check of <strong>Test</strong> Antenna________________________________________311<br />

H4 ACTIVATION ANTENNAS ______________________________________________ 312<br />

H4.1 General ________________________________________________________________312<br />

H4.2 Activation Antenna Design ________________________________________________313<br />

H4.2.1 Overall Design _______________________________________________________________313<br />

H4.2.2 Spacer ______________________________________________________________________314<br />

H4.2.3 Loop _______________________________________________________________________314<br />

H4.2.3.1 General ________________________________________________________________314<br />

H4.2.3.2 Capacitors ______________________________________________________________314<br />

H4.2.3.3 Printed Circuit Board (PCB) ________________________________________________314<br />

H4.2.3.4 27.095 MHz Trans<strong>for</strong>mer __________________________________________________315<br />

H4.2.3.5 Current Sense Trans<strong>for</strong>mer and Current Probe __________________________________315<br />

H4.2.4 Connector Holder _____________________________________________________________315<br />

H4.2.5 Balun _______________________________________________________________________315<br />

H4.3 4.2 MHz Antenna Design _________________________________________________316<br />

H4.4 Tuning of Activation Antenna _____________________________________________316<br />

H4.5 Per<strong>for</strong>mance Check of Activation Antenna __________________________________316<br />

H5 BALUNS____________________________________________________________ 317<br />

H5.1 General ________________________________________________________________317<br />

H5.2 General Purpose Balun Design_____________________________________________317<br />

H5.2.1 Overall Design _______________________________________________________________317<br />

H5.2.2 Toroid ______________________________________________________________________318

Page 16 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

H5.3 Reference Loop Balun Design _____________________________________________318<br />

H5.3.1 Overall Design _______________________________________________________________318<br />

H5.3.2 Toroid ______________________________________________________________________318<br />

H5.4 Current Sense Balun Design_______________________________________________319<br />

H5.4.1 Overall Design _______________________________________________________________319<br />

H5.4.2 Toroid ______________________________________________________________________319<br />

H5.4.3 Current Probe ________________________________________________________________320<br />

H5.5 Calibration of the Current Sense Balun _____________________________________320<br />

ANNEX I (INFORMATIVE), BIBLIOGRAPHY _____________________________________ 322<br />

ANNEX J (INFORMATIVE), TEST TOOL FOR LZB CABLE TESTING ___________________ 324<br />

J1 GENERAL __________________________________________________________ 324<br />

J2 OVERALL DESIGNS __________________________________________________ 324<br />

J2.1 General __________________________________________________________________324<br />

J2.2 Vertical Loop used <strong>for</strong> 4.2 MHz Balise <strong>Test</strong>s ___________________________________324<br />

J2.3 Horizontal Loop used <strong>for</strong> 4.2 MHz On-board Equipment <strong>Test</strong>s____________________326<br />

J2.4 Vertical Loop used <strong>for</strong> 27 MHz <strong>Test</strong>s _________________________________________329<br />

J3 PRINTED CIRCUIT BOARD AND COMPONENTS _____________________________ 331<br />

J4 TUNING OF THE LZB LOOP____________________________________________ 332

Page 17 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

1 Introduction<br />

1.1 Application Range<br />

This Norm is part of the overall set of normative background that constitutes the basis <strong>for</strong> the European Union<br />

Directive 96/48/EC on trans-European High Speed Railway Network Interoperability, and <strong>for</strong> the relevant Technical<br />

<strong>Specification</strong> <strong>for</strong> Interoperability (TSI).<br />

The TSI (Technical <strong>Specification</strong> <strong>for</strong> Interoperability) defines the concept of “Technical Interoperability” that<br />

applies to the “Constituents” of the Control-Command Sub-System.<br />

As far as the Balise Location and Transmission System is concerned, the wayside Balises and the complete Onboard<br />

ATP/ATC equipment, including the Balise Location and Transmission Functionality, are interoperability<br />

“Constituents” considered in this Norm.<br />

Wherever this document refers to “Part 1 of this Norm”, it means referring to UNISIG SUBSET-036.<br />

1.2 Scope<br />

This Part 2 of the Norm defines the specific set of verifications required <strong>for</strong> certification of con<strong>for</strong>mity and<br />

suitability <strong>for</strong> use <strong>for</strong> all the <strong>Eurobalise</strong> data transmission products, as defined by Part 1.<br />

These units are the Balises, (standing alone fixed data Balises, or controlled data Balises linked to the wayside<br />

signalling system) and the On-board Antenna Units integrated with the transmission functionality of the overall<br />

On-board ATP/ATC equipment.<br />

The verifications dealt with in this Norm are aimed at ensuring full and safe interoperability between wayside<br />

and On-board equipment of any supplier. For this purpose, this part of the Norm mostly addresses all those<br />

requirements that are specifically stated as mandatory in the Part 1.<br />

Some interesting non-mandatory requirements (defined as recommended, preferred, or optional solutions) are<br />

also considered in the annexes herein. This is <strong>for</strong> the purposes of supporting product interchangeability and<br />

maintainability.<br />

The “<strong>Eurobalise</strong>” denomination can only identify those commercial products that have got certification of con<strong>for</strong>mity<br />

compliance, based on the test requirements of the present Norm, by an officially recognised body.<br />

This part of the Norm specifies detailed functional and non-functional test requirements <strong>for</strong> the Balise, identified<br />

as a basic wayside constituent of interoperability.<br />

A special focus is given to the air-gap interface, where the Balise interacts with the On-board equipment. The<br />

air-gap requirements <strong>for</strong> the Balise have been defined in all needed details in Part 1 of the Norm.<br />

The interface of the Balise with the wayside equipment is also considered, mainly <strong>for</strong> the purpose of interchangeability<br />

of wayside components.<br />

This part of the Norm specifies a set of functional and non-functional test requirements <strong>for</strong> the transmission<br />

parts of the On-board equipment, which are deemed indispensable <strong>for</strong> the purpose of interoperability. Also in<br />

this case, a special focus is given to the air-gap interface, where the On-board Antenna Unit interacts with the<br />

wayside Balise.

Page 18 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

Compared with the Balise case, only a minimum set of mandatory test requirements has been defined <strong>for</strong> the Onboard<br />

equipment. This allows any kind of optimisation, in costs and per<strong>for</strong>mance, <strong>for</strong> the overall architecture of<br />

the On-board system, while still ensuring interoperability.<br />

The specific test set-ups presented herein are recommendations only, and should primarily be regarded of principal<br />

nature. However, they are detailed enough to provide a solid basis <strong>for</strong> designing actual test set-ups, and<br />

they do include hints on important properties. Modifications are allowed as long the measurement accuracy is<br />

maintained, the same results are obtained, and the same properties are explored. There might in some cases be a<br />

need <strong>for</strong> additional precautions not to destroy specific instruments (due to high power levels).

Page 19 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

2 Normative References<br />

This Norm incorporates, by dated or undated references, provisions from other publications. These normative<br />

references are cited at the appropriate places in the text, and the publications are listed hereafter. For dated<br />

references, subsequent amendments to, or revisions of, any of these publications apply to this Norm only when<br />

incorporated herein by amendment or revision. For undated references, the latest edition of the publication<br />

referred to apply.<br />

Additional in<strong>for</strong>mative references are included in Annex I, Bibliography.<br />

I. UNISIG <strong>Specification</strong>s:<br />

A. UNISIG SUBSET-036, <strong>FFFIS</strong> <strong>for</strong> <strong>Eurobalise</strong><br />

B. UNISIG SUBSET-023, Glossary of UNISIG Terms and Abbreviations<br />

3 Terminology and Definitions<br />

3.1 Acronyms and Abbreviations<br />

In general, the acronyms and abbreviations of Part 1 of this Norm (UNISIG SUBSET-036), and of UNISIG<br />

SUBSET-023, apply. The following list of additional acronyms applies within this part of the Norm:<br />

Acronym<br />

APT<br />

CS<br />

DUT<br />

GUI<br />

ID<br />

LRRT<br />

LTMS<br />

LTOM<br />

OLTG<br />

PCB<br />

RF<br />

RSG<br />

VSWR<br />

Explanation<br />

Antenna Positioning Tool<br />

Current Sense<br />

Device Under <strong>Test</strong><br />

Graphical User Interface<br />

Identity<br />

Laboratory Reference Receiver Tool<br />

Laboratory <strong>Test</strong> and Measurement System<br />

Laboratory Time and Odometer Module<br />

Off-line Telegram Generator<br />

Printed Circuit Board<br />

Radio Frequency<br />

Reference Signal Generator<br />

Voltage Standing Wave Ratio

Page 20 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

The following additional abbreviations apply:<br />

Abbreviation<br />

Char<br />

Tel.<br />

Explanation<br />

Character<br />

Telegram<br />

3.2 Definitions<br />

In general, the definitions of Part 1 of this Norm (UNISIG SUBSET-036), and of UNISIG SUBSET-023, apply.<br />

3.3 Influence of Tolerances<br />

The general requirement stated in Part 1 of this Norm regarding test tolerances should be observed. The requirements<br />

in the specification limits do not involve the error of the test equipment that is used in the test process,<br />

unless this is expressly written. This means that a maximum limit value shall be decreased, and a minimum<br />

limit value shall be increased with the applicable equipment error during test. Thus, the use of a very accurate<br />

test tool widens the allowed tolerances <strong>for</strong> the actual test object.<br />

The number of digits, which the specific parameter values are expressed in, regarding the limits stated within<br />

Part 1 of this Norm are not to be regarded as significant digits. The tolerances state the accuracy, and thus the<br />

significance of the digits. Thus, they (the expressed number of digits) do not imply a certain required accuracy<br />

or resolution. The required resolution and accuracy must be evaluated by other means. A general principle is<br />

that the accuracy/resolution of test tools should be in the order of 1 % (or possibly 5 %) of the specified tolerance<br />

range (if feasible), or better. Using better tools allow a wider tolerance range <strong>for</strong> the actual device under<br />

test (DUT). In some cases this high accuracy is not feasible (can not be achieved in a reasonable way), but the<br />

reason <strong>for</strong> this shall be explained/justified.<br />

In this Norm, calibration procedures and calibration set-ups are repeated in each test description. The spirit is<br />

neither that this reflects the sequence of the activities, nor that re-calibration is frequently required. The important<br />

thing is to calibrate when deemed necessary to achieve the required accuracy.

Page 21 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4 <strong>Test</strong>s of the Up-link Balise<br />

4.1 Reference <strong>Test</strong> Configurations<br />

4.1.1 General<br />

The following conditions should apply <strong>for</strong> the majority of the tests where no specific environmental or operational<br />

condition is required.<br />

Ambient temperature 25 °C ± 10 °C<br />

Relative humidity 25 % to 75 %<br />

Atmospheric Pressure<br />

86 kPa to 106 kPa<br />

Debris in the air-gap<br />

None<br />

Tele-powering mode<br />

CW<br />

EMC noise within the Up-link frequency band<br />

Negligible<br />

The environmental conditions of the table above should be maintained as far as reasonably possible. Monitoring<br />

of the conditions should apply if it can not be guaranteed that the limits are fulfilled.<br />

In order to minimise the possible influence from the surrounding environment, there shall be a volume around<br />

the Antenna Unit and the Balise under test that is free from metallic objects. The minimum extent of this volume<br />

is defined in Figure 1. This volume is also referred to as “free space“ condition. The space below 0.4 m<br />

(but above 0.7 m) underneath the Balise shall not contain any solid metal planes, and only a few metallic supports<br />

are allowed within 0.7 m underneath the Balise.<br />

Antenna<br />

center<br />

X<br />

center<br />

Balise<br />

0.4 m / 0.7 m<br />

Z<br />

Min. 1 m<br />

No metallic objects are<br />

allowed in this zone.<br />

Min. 1 m<br />

Min. 1 m<br />

Antenna<br />

Balise<br />

Min. 1 m<br />

Min. 1 m<br />

Min. 1 m<br />

Min. 1 m<br />

Figure 1: Definition of “free space” around the sub-system under test

Page 22 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.1.2 Monitored Interfaces<br />

The following interfaces are used:<br />

• Interface ‘A’ (the air-gap interface).<br />

• Interface ‘C’ (the Balise controlling interface).<br />

4.1.3 <strong>Test</strong> Tools and Procedures<br />

The following list summarises the herein-defined tests:<br />

1. Verification of Interface ‘A’ (air-gap):<br />

1.1. Field con<strong>for</strong>mity in the contact zone, and in the side-lobe zone, <strong>for</strong> the Tele-powering field received<br />

by the Balise;<br />

1.2. Field con<strong>for</strong>mity in the contact zone, side lobe zone, and cross-talk protected zone, <strong>for</strong> the Uplink<br />

field generated by the Balise;<br />

1.3. Compliance of the electrical characteristics of the Up-link signal;<br />

2. Verification of Balise controlling interface <strong>for</strong> controlled Balises:<br />

2.1. Up-link data signal characteristics at Interface ‘C1’;<br />

2.2. Biasing signal characteristics at Interface ‘C6’;<br />

2.3. Return Loss at the source end (LEU output) of Interfaces ‘C1’ and ‘C6’;<br />

2.4. Switching from Interface ‘C1’ telegram to the Default Telegram when an invalid signal is temporarily<br />

or permanently simulated at Interface ‘C1’;<br />

2.5. Blocking signal characteristics at Interface ‘C4’ (where applicable).<br />

3. Verification of internal functionality:<br />

3.1. I/O characteristics;<br />

3.2. Balise impedance with respect to the Tele-powering source;<br />

3.3. Time delay between data at Interfaces ‘C1’ and ‘A1’ (controlled Balises only);<br />

3.4. Start-up behaviour of the Up-link signal;<br />

3.5. KER compatible response with a “non-toggling” Tele-powering signal.<br />

4. Verification of cross-talk immunity with nearby cables (transversal cables according to the specific<br />

installation constraints given by the manufacturer).<br />

5. Verification of the compliance with some specific EMC requirements.<br />

The following tools are anticipated <strong>for</strong> the Balise tests:<br />

• <strong>Test</strong> Management System, used <strong>for</strong> co-ordinating the measurements, controlling the other tools of<br />

the test set-up, and <strong>for</strong> logging and reporting the test results;<br />

• Antenna Positioning Tool;<br />

• Reference Loops (Standard or Reduced Size type) equipped with Baluns;<br />

• <strong>Test</strong> and Activation Antennas;<br />

• Reference Signal Generators;<br />

• Telegram Generator;<br />

• Reference Receiver;<br />

• RF instruments and accessories of general use;<br />

• Reference Units <strong>for</strong> debris, metallic masses, and cables.

Page 23 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.2 Laboratory <strong>Test</strong>s<br />

4.2.1 Generic <strong>Test</strong> and Calibration Set-up notes<br />

The following aspects shall be respected <strong>for</strong> all test set-ups within this clause (clause 4). For some set-ups all<br />

aspects apply, but <strong>for</strong> others only some apply. The applicability is evident from the recommended test set-ups<br />

presented herein.<br />

• A spectrum analyser or similar equipment may substitute any power meter. However, this device shall be<br />

calibrated against a power meter prior to the test.<br />

• It shall be verified that all harmonics are suppressed by at least 40 dB if power meters are used. Otherwise,<br />

sufficient filtering shall be per<strong>for</strong>med.<br />

• All input and output ports of the devices in accordance with clause H3 on page 306 and H4 on page 312<br />

shall be equipped with suitable baluns (these are part of the defined devices).<br />

• The attenuators connected be<strong>for</strong>e and after the RF power amplifier shall be positioned as close as possible<br />

to the amplifier, and are used <strong>for</strong> ensuring good VSWR. The attenuator on the amplifier output is also used<br />

<strong>for</strong> protecting the amplifier from reflected power.<br />

• It is important that all cabling is of low loss double shielded type (e.g., RG 214). Furthermore, the cables<br />

shall be “de-bugged” using suitable ferrite clamps, evenly spaced along the cables, at distances less than<br />

70 cm. The core material in the ferrite clamps shall be “Amidon 43” or equivalent.<br />

• The calibrations and tests shall be per<strong>for</strong>med with Balise telegram of type 1 defined in clause A2 of Annex<br />

A on page 157, unless otherwise explicitly stated. The Balise, the Reference Loop and the “cable” (during<br />

cross-talk tests) shall transmit the same telegram.<br />

• RMS values are applicable unless otherwise explicitly stated.<br />

• Iron bars shall be at least 50 cm from metal objects like a concrete floor containing iron rein<strong>for</strong>cements.<br />

• The cable carrying the 27 MHz signal to the <strong>Test</strong> Antenna (see clause H3 of Annex H on page 306) shall be<br />

identical throughout the entire test process.<br />

• It is essential that the Reference Loops used during the tests fulfil the requirements of clause B2 of Annex B<br />

on page 163, and are characterised prior to testing. The procedure <strong>for</strong> characterisation of the equipment is<br />

defined by sub-clause B2.6 of Annex B on page 168.<br />

• Ferrite devices shall be used in order to reduce the RF field effect on the measurements. A balun basically<br />

consists of a ferrite core (see clause H5 of Annex H on page 317 <strong>for</strong> more details). A balun shall be positioned<br />

at the end of the cable, i.e., at the Reference Loop connector, unless otherwise explicitly stated.<br />

• All distances are in millimetres unless explicitly otherwise stated.<br />

• The orientation of the Reduced Size Balise/Reference Loop is irrelevant unless otherwise explicitly stated.<br />

However, calibrations and measurements shall be per<strong>for</strong>med with the same orientation.<br />

• In case of testing with some debris conditions, please observe the increase of flux levels (when applicable)<br />

as defined in Part 1 of this Norm.

Page 24 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

• In case of verifying characteristics at the upper extreme temperature, it is judged sufficient to per<strong>for</strong>m testing<br />

with constant temperature only (without concurrent solar radiation). It is judged relevant that the maximum<br />

increase in temperature that would have been caused by the (non-existing) specified solar radiation<br />

level (see sub-clause 4.9 of EN 50125-3), in the worst Balise conditions, is 30 °C. This shall be considered<br />

when applying the requirements of Part 1 of this Norm, unless the manufacturer can provide evidence that a<br />

lower temperature increase applies.<br />

• The defined installation case with metallic plane in the extreme vicinity of the Balise may require specifically<br />

tuned Balises (see UNISIG SUBSET-036). In such a case, the metallic plane is considered an integral<br />

part of the Balise. However, please observe that field con<strong>for</strong>mity requirements apply to free air conditions.<br />

• For specifically tuned Balises (with an integral metallic plane), the herein defined “Case 1” and “Case 2”<br />

metallic planes do not apply.<br />

• In general, testing the condition with the metallic plane in the extreme vicinity of the Balise is optional and<br />

applies only to products stated to fulfil this specific installation condition.<br />

• If not otherwise explicitly stated, the defined “Case 1” metallic plane condition applies <strong>for</strong> Balise testing<br />

(when metallic plane conditions apply).<br />

• Applicable sources of data <strong>for</strong> controlled Balises versus test cases are clarified in sub-clause C7.3 on page<br />

209. 5<br />

5<br />

Sub-clause C7.3 does not introduce any new test cases relative to the previous version of this test specification. It merely<br />

clarifies the intent of the main text.

Page 25 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.2.2 Up-link Field Con<strong>for</strong>mity<br />

4.2.2.1 General<br />

This sub-clause defines the test procedure <strong>for</strong> Up-link field con<strong>for</strong>mity testing. It also includes the various test<br />

set-ups that are recommended. The test procedures include two different steps with partially different test setups.<br />

The steps are:<br />

• Calibration of 4.2 MHz Balise loop current I loop .<br />

• Balise con<strong>for</strong>mity measurements.<br />

There are two versions of the <strong>Test</strong> Antenna used in this test procedure. The first is the Standard <strong>Test</strong> Antenna,<br />

or simply <strong>Test</strong> Antenna. The second is the Modified <strong>Test</strong> Antenna. This device has no 27 MHz loop but is<br />

apart from this identical to the Standard <strong>Test</strong> Antenna. Both versions are described in clause H3 of Annex H on<br />

page 306.<br />

There are also two versions of Activation Antennas. The first is the standard Activation Antenna with a 27 MHz<br />

loop. The second device is modified so that the 27 MHz loop is replaced by a 4.2 MHz loop. This device is<br />

only used as a measurement probe, and is identical to the Activation Antenna apart from the change of loops.<br />

This device is named 4.2 MHz Antenna. Both versions are described in clause H4 of Annex H on page 312.<br />

The calibrations and tests shall be per<strong>for</strong>med with a Balise telegram of type 1 defined in clause A2 of Annex A<br />

on page 157. Both the Balise and the Reference Loop shall transmit the same telegram. In all tests and calibrations<br />

with controlled Balise, telegrams transmitted via the Balise controlling interface shall be used (with nominal<br />

Balise controlling interface conditions).<br />

Balise con<strong>for</strong>mity measurements shall be per<strong>for</strong>med during free air conditions only.

Page 26 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.2.2.2 Calibration of 4.2 MHz Balise Loop Current in the Contact Zone<br />

4.2.2.2.1 Calibration Configuration<br />

A proposed calibration set-up is shown in Figure 2 below. Clause F1 of Annex F on page 287 gives an example<br />

of suitable test equipment. Power Meter 2 shall be able to accurately measure signal levels down to -55 dBm. If<br />

Power Meter 2 is substituted by <strong>for</strong> instance a spectrum analyser, then the measurement bandwidth of this device<br />

shall be 1.2 MHz. The preamplifier, and the filter be<strong>for</strong>e it, shall be connected as close as possible to the <strong>Test</strong><br />

Antenna. The filter after the preamplifier shall be connected as close as possible to the Power Meter 2. See also<br />

sub-clause 4.2.1 on page 23.<br />

Power<br />

Meter 3<br />

P lc<br />

11.<br />

Attenuator<br />

Balun<br />

14.<br />

P in<br />

3.<br />

2.<br />

13.<br />

RF<br />

Amplifier<br />

Attenuator<br />

Signal<br />

Generator<br />

50 Ω<br />

50 Ω<br />

C.S.<br />

18.<br />

Activation<br />

Antenna<br />

Reference Loop<br />

Interface ‘A’<br />

<strong>Test</strong> Antenna<br />

Filter 12.<br />

4.2 MHz<br />

7.<br />

6.<br />

15.<br />

Power<br />

Meter 2<br />

P M2<br />

12.<br />

Filter<br />

Pre-amplifier 16.<br />

Figure 2: <strong>Test</strong> set-up <strong>for</strong> calibration of 4.2 MHz Balise Loop Current

Page 27 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />

4.2.2.2.2 Calibration Abstract<br />

This calibration procedure will give a reference value P 42RL <strong>for</strong> each measurement point, defined in clause C1 of<br />

Annex C on page 200, which shall be compared with the corresponding value P 42BA <strong>for</strong> the Balise. The reference<br />

value P 42RL is reflecting the flux received by the <strong>Test</strong> Antenna, and measured by Power Meter 2 (P M2 ) and<br />

then compensated, and called P 42RL . The calibration is per<strong>for</strong>med with the current I u2 /B through the Reference<br />

Loop. The current through the Reference Loop is monitored by Power Meter 3 (P lc ).<br />

4.2.2.2.3 Calibration Procedure<br />

1. Position the Modified <strong>Test</strong> Antenna (without 27 MHz loop) in position [X = 0, Y = 0, Z = 220] relative to<br />

the Reference Loop. Be sure to position the electrical centre of the <strong>Test</strong> Antenna aligned with the electrical<br />

centre of the Reference Loop. Also check that the X, Y, and Z axes of the Reference Loop are correctly<br />

aligned to the X, Y, and Z axes of the positioning system. Position the Activation Antenna, in position<br />

[X = 440, Y = 220, Z = 0] relative to the Reference Loop. This position shall be fixed during the<br />

calibration.<br />

2. Set the Signal Generator to generate the FSK signal that carries telegram type 1.<br />

3. Adjust the Signal Generator amplitude in order to achieve a current of approximately I u2 /B through the<br />

Reference Loop.<br />

For calibration and compensation of the Current Sense Balun see clause H5 of Annex H on page 317.<br />

Record the reading of Power Meter 3 and call it P lc .<br />

4. Record the reading of Power Meter 2 (called P M2 ) and Power Meter 3 (called P M3 ).<br />

Repeat<br />

<strong>for</strong> each<br />

position<br />

5. Compensate the P M2 reading with the difference between the P M3 reading and the power level P lc ,<br />

<strong>for</strong> I u2 /B measured in step 3. 6 Call the new value P 42RL .<br />

P 42RL = P M2 + (P lc - P M3 ), all values in dBm.<br />

6. Per<strong>for</strong>m steps 4 and 5 <strong>for</strong> all the [X, Y, Z] positions listed in clause C1 of Annex C on page 200.<br />

6<br />

The reason <strong>for</strong> this compensation is that the relative accuracy <strong>for</strong> the value of P 42RL between the different positions needs<br />

to be very good, and that this procedure compensates <strong>for</strong> power amplifier drift and impedance changes in the Reference<br />

Loop when moving the <strong>Test</strong> Antenna.

Page 28 of 332<br />

SUBSET-085, Issue 2.2.2<br />

November 9, 2007<br />