Abstract

The hydrogenation of coal-based acetylene to ethylene is an important approach to establishing a non-oil route to ethylene production, yet it suffers from high H2 consumption as well as a high energy input. Here we report a H2-free acetylene hydrogenation process achieved by directly using water as the hydrogen source and low-cost CO as the oxygen acceptor over a Au/α-MoC catalyst. The process delivers over 99% acetylene conversion and a high ethylene selectivity of 83% at 80 °C, surpassing the hydrogenation process using H2 as the hydrogen source. Mechanistic studies have revealed that in situ-generated hydroxyl species from water dissociation at the boundary of Au and α-MoC, serving as mild reductants, enable the selective semi-hydrogenation of acetylene with residual O removed by CO. This process circumvents the need for H2 in the classical route and opens avenues for energy-efficient acetylene hydrogenation by water at low temperature.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information files or from the corresponding author on reasonable request. The atomic structures and vibrational frequencies for the intermediate states are available in the figshare repository (https://doi.org/10.6084/m9.figshare.22768451). Source data are provided with this paper.

References

Gao, Y. et al. Recent advances in intensified ethylene production—a review. ACS Catal. 9, 8592–8621 (2019).

Schobert, H. Production of acetylene and acetylene-based chemicals from coal. Chem. Rev. 114, 1743–1760 (2013).

Trotus, I. T., Zimmermann, T. & Schüth, F. Catalytic reactions of acetylene: a feedstock for the chemical industry revisited. Chem. Rev. 114, 1761–1782 (2013).

Othmer, K. (ed.) Encyclopedia of Chemical Technology (Wiley, 2003).

Corma, A. Introduction: chemicals from coal, alkynes, and biofuels. Chem. Rev. 114, 1545–1546 (2014).

Guo, Y. et al. Photo-thermo semi-hydrogenation of acetylene on Pd1/TiO2 single-atom catalyst. Nat. Commun. 13, 2648 (2022).

Moon, J. et al. Discriminating the role of surface hydride and hydroxyl for acetylene semihydrogenation over ceria through in situ neutron and infrared spectroscopy. ACS Catal. 10, 5278–5287 (2020).

Gu, J. et al. Synergizing metal–support interactions and spatial confinement boosts dynamics of atomic nickel for hydrogenations. Nat. Nanotechnol. 16, 1141–1149 (2021).

Studt, F. et al. Identification of non-precious metal alloy catalysts for selective hydrogenation of acetylene. Science 320, 1320–1322 (2008).

Huang, F. et al. Atomically dispersed Pd on nanodiamond/graphene hybrid for selective hydrogenation of acetylene. J. Am. Chem. Soc. 140, 13142–13146 (2018).

Ford, P. C. The water gas shift reaction: homogeneous catalysis by ruthenium and other metal carbonyls. Acc. Chem. Res. 14, 31–37 (1981).

Ratnasamy, C. & Wagner, J. P. Water gas shift catalysis. Catal. Rev. 51, 325–440 (2009).

LeValley, T. L., Richard, A. R. & Fan, M. The progress in water gas shift and steam reforming hydrogen production technologies—a review. Int. J. Hydrogen Energy 39, 16983–17000 (2014).

Shi, R. et al. Room-temperature electrochemical acetylene reduction to ethylene with high conversion and selectivity. Nat. Catal. 4, 565–574 (2021).

Bu, J. et al. Selective electrocatalytic semihydrogenation of acetylene impurities for the production of polymer-grade ethylene. Nat. Catal. 4, 557–564 (2021).

Wang, S. et al. Highly efficient ethylene production via electrocatalytic hydrogenation of acetylene under mild conditions. Nat. Commun. 12, 7072 (2021).

Durante, C. An electrochemical way to pure ethylene. Nat. Catal. 4, 537–538 (2021).

Gokhale, A. A., Dumesic, J. A. & Mavrikakis, M. On the mechanism of low-temperature water gas shift reaction on copper. J. Am. Chem. Soc. 130, 1402–1414 (2008).

Polo-Garzon, F. et al. Elucidation of the reaction mechanism for high-temperature water gas shift over an industrial-type copper–chromium–iron oxide catalyst. J. Am. Chem. Soc. 141, 7990–7999 (2019).

Flytzani-Stephanopoulos, M. Gold atoms stabilized on various supports catalyze the water–gas shift reaction. Acc. Chem. Res. 47, 783–792 (2014).

Deng, Y. et al. Molybdenum carbide: controlling the geometric and electronic structure of noble metals for the activation of O–H and C–H bonds. Acc. Chem. Res. 52, 3372–3383 (2019).

Dong, J., Fu, Q., Jiang, Z., Mei, B. & Bao, X. Carbide-supported Au catalysts for water–gas shift reactions: a new territory for the strong metal–support interaction effect. J. Am. Chem. Soc. 140, 13808–13816 (2018).

Yang, M. et al. Catalytically active Au-O(OH)x species stabilized by alkali ions on zeolites and mesoporous oxides. Science 346, 1498–1501 (2014).

Zhai, Y. et al. Alkali-stabilized Pt-OHx species catalyze low-temperature water-gas shift reactions. Science 329, 1633–1636 (2010).

Cao, S. et al. High-loading single Pt atom sites [Pt-O(OH)x] catalyze the CO PROX reaction with high activity and selectivity at mild conditions. Sci. Adv. 6, eaba3809 (2020).

Jia, J., Haraki, K., Kondo, J. N., Domen, K. & Tamaru, K. Selective hydrogenation of acetylene over Au/Al2O3 catalyst. J. Phys. Chem. B 104, 11153–11156 (2000).

Pei, G. X. et al. Ag alloyed Pd single-atom catalysts for efficient selective hydrogenation of acetylene to ethylene in excess ethylene. ACS Catal. 5, 3717–3725 (2015).

Fu, X. P. et al. Direct identification of active surface species for the water–gas shift reaction on a gold–ceria catalyst. J. Am. Chem. Soc. 141, 4613–4623 (2019).

Qian, K. et al. Catalytically active structures of SiO2-supported Au nanoparticles in low-temperature CO oxidation. Catal. Sci. Technol. 3, 679–687 (2013).

Zhang, P. & Sham, T. K. Tuning the electronic behavior of Au nanoparticles with capping molecules. Appl. Phys. Lett. 81, 736–738 (2002).

Zhang, P. & Sham, T. K. X-ray studies of the structure and electronic behavior of alkanethiolate-capped gold nanoparticles: the interplay of size and surface effects. Phys. Rev. Lett. 90, 245502 (2003).

Lin, L. et al. Low-temperature hydrogen production from water and methanol using Pt/α-MoC catalysts. Nature 544, 80–83 (2017).

Yao, S. et al. Atomic-layered Au clusters on α-MoC as catalysts for the low-temperature water-gas shift reaction. Science 357, 389–393 (2017).

Pantelouris, A., Kiiper, G., Homes, J., Feldmann, C. & Jansen, M. Anionic gold in Cs3AuO and Rb3AuO established by X-ray absorption spectroscopy. J. Am. Chem. Soc. 117, 11749–11753 (1995).

Campbell, C. T. Electronic perturbations. Nat. Chem. 4, 597–598 (2012).

Si, R. & Flytzani-Stephanopoulos, M. Shape and crystal-plane effects of nanoscale ceria on the activity of Au-CeO2 catalysts for the water–gas shift reaction. Angew. Chem. Int. Ed. 47, 2884–2887 (2008).

Miller, J. T. et al. The effect of gold particle size on Au–Au bond length and reactivity toward oxygen in supported catalysts. J. Catal. 240, 222–234 (2006).

Murugappan, K. et al. Operando NAP-XPS unveils differences in MoO3 and Mo2C during hydrodeoxygenation. Nat. Catal. 1, 960–967 (2018).

Wan, C., Regmi, Y. N. & Leonard, B. M. Multiple phases of molybdenum carbide as electrocatalysts for the hydrogen evolution reaction. Angew. Chem. Int. Ed. 53, 6407–6410 (2014).

Zhang, X. et al. A stable low-temperature H2-production catalyst by crowding Pt on α-MoC. Nature 589, 396–401 (2021).

Liu, P. & Rodriguez, J. A. Water-gas-shift reaction on molybdenum carbide surfaces: essential role of the oxycarbide. J. Phys. Chem. B 110, 19418–19425 (2006).

de Oliveira, P. F. M. et al. Tandem X-ray absorption spectroscopy and scattering for in situ time-resolved monitoring of gold nanoparticle mechanosynthesis. Chem. Commun. 56, 10329–10332 (2020).

Liu, X. et al. Strong metal–support interactions between gold nanoparticles and ZnO nanorods in CO oxidation. J. Am. Chem. Soc. 134, 10251–10258 (2012).

Pozdnyakova, O. et al. Preferential CO oxidation in hydrogen (PROX) on ceria-supported catalysts, part I: oxidation state and surface species on Pt/CeO2 under reaction conditions. J. Catal. 237, 1–16 (2006).

Gao, X., Yu, X.-Y. & Chang, C. R. Perceptions on the treatment of apparent isotope effects during the analyses of reaction rate and mechanism. Phys. Chem. Chem. Phys. 24, 15182–15194 (2022).

de la Osa, A. R., De Lucas, A., Romero, A., Valverde, J. L. & Sánchez, P. Kinetic models discrimination for the high pressure WGS reaction over a commercial CoMo catalyst. Int. J. Hydrogen Energy 36, 9673–9684 (2011).

Fu, Q., Saltsburg, H. & Flytzani-Stephanopoulos, M. Active nonmetallic Au and Pt species on ceria-based water-gas shift catalysts. Science 301, 935–938 (2003).

Li, Y., Fu, Q. & Flytzani-Stephanopoulos, M. Low-temperature water-gas shift reaction over Cu- and Ni-loaded cerium oxide catalysts. Appl. Catal. B 27, 179–191 (2000).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Hafner, J. Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H–Pu. J. Chem. Phys. 132, 154104 (2010).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the damping function in dispersion corrected density functional theory. J. Comput. Chem. 32, 1456–1465 (2011).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Alavi, A., Hu, P., Deutsch, T., Silvestrelli, P. L. & Hutter, J. CO oxidation on Pt(111): an ab initio density functional theory study. Phys. Rev. Lett. 80, 3650–3653 (1998).

Michaelides, A. & Hu, P. Insight into microscopic reaction pathways in heterogeneous catalysis. J. Am. Chem. Soc. 122, 9866–9867 (2000).

Michaelides, A. & Hu, P. Catalytic water formation on platinum: a first-principles study. J. Am. Chem. Soc. 123, 4235–4242 (2001).

Hjorth Larsen, A. et al. The atomic simulation environment—a Python library for working with atoms. J. Phys. Condens. Matter 29, 273002 (2017).

Porosoff, M. D., Yang, X., Boscoboinik, J. A. & Chen, J. G. Molybdenum carbide as alternative catalysts to precious metals for highly selective reduction of CO2 to CO. Angew. Chem. Int. Ed. 53, 6705–6709 (2014).

Acknowledgements

Financial support by the National Natural Science Foundation of China (grant nos. 21890753, 21988101, 22225204 and 22372019), the Strategic Priority Research Program of the Chinese Academy of Sciences (grant no. XDB36030200), the Key Research Program of Frontier Sciences of the Chinese Academy of Sciences (grant no. QYZDB-SSW-JSC020) and the Fundamental Research Funds for the Central Universities (DUT21LK09/82231014) is acknowledged. We thank the staff at the BL14W1 beamline of the Shanghai Synchrotron Radiation Facilities for assistance with the EXAFS and XANES measurements. We also thank C. Meng, W. Yu, Y. Tu and K. Zhu from DICP for help with the in situ XPS, TPD, XAS and NMR measurements.

Author information

Authors and Affiliations

Contributions

D.D. conceived the project. R.H. carried out the experiments. M.X. and L.Y. performed the DFT calculations. Y.Z. and M.L. conducted the AC-HRTEM measurements. Yao Wei and Z.J. helped with the XAS analysis. C.G. and B.Z. helped with the kinetic measurements. X.H., Q.C., Yan Wei, J.H. and X.C. helped with other catalyst characterization. All authors contributed to the scientific discussion. R.H., M.X., L.Y. and D.D. wrote and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Catalysis thanks Mohammednoor Altarawneh and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Screening of catalyst under different reaction conditions.

a,b, Reaction conditions: 30 mg catalyst, 80 °C, 3.2 MPa (CO/C2H2/Ar = 6:5:89), 15 ml H2O, 20 hours. c, In-situ catalytic cycle. Reaction conditions: 100 mg catalyst, 80 °C, 3.2 MPa (CO/C2H2/Ar = 6:5:89), 10 ml H2O. The reaction was cycled by charging new feed gas into the system without separating the catalyst and solution. TOF is calculated as specific mole rate of C2H4 production on per mole of Au. d, The reaction temperature and time were changed to 220 °C, and 2 hours with other conditions unchanged. e, ICP-OES results.1st and 5th mean the results after one or five cycles.

Extended Data Fig. 2 Bulk-phase structure characterizations of catalysts.

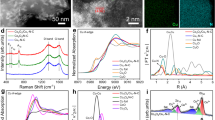

a, PXRD patterns of different catalysts before and after reaction. b,c, AC-HRTEM images and particle size distribution diagrams of 6Au/α-MoC (b) and 1Au/α-MoC (c) catalyst. It presents nearly the same size of α-MoC. The size of Au was measured by elemental mapping images in Extended Data Fig. 4.

Extended Data Fig. 3 Ex-situ and in-situ XAS spectra at the Au L3-edge of different catalysts.

a, Curve fitting parameters for Au L3-edge EXAFS for different samples. The distance of Au-Au and Au-Mo is from the crystal structure of [Au 1100138] and [Mo 4317354]; *: Average coordination number; #: distance between absorber and backscatter atoms; ǁ: difference of potential of sample and standard; ǂ: Debye-Waller factor. The data are not phase-corrected. Error bars represent the fitting error from EXAFS. b,c, Au L3-edge EXAFS (points) and the curvefit (line) for different samples in R space and k3-weighted k space. d,e, In-situ XANES (d) and Fourier-transform EXAFS spectra in the R-space (e) at the Au L3-edge for the 6Au/α-MoC catalyst during the CO-H2O-AHE reaction at 25, 80 and 100 °C. The inset shows the enlarged regions of the Au L3-edge absorption edge.

Extended Data Fig. 4 AC-HRTEM images and elemental mapping images of 6Au/α-MoC.

a,b AC-HRTEM images, c-f Elemental mapping images of Mo (c), Au (d), C (e), and O (f).

Extended Data Fig. 5 XPS of the Au/α-MoC catalysts with different Au loadings and the used 6Au/α-MoC catalyst.

a, Mo 3d5/2 XPS spectra of different catalysts. b, C 1s XPS spectra of catalysts. c, Element and component content of different catalysts fitted by XPS. Mo 3d5/2 XPS spectra (a) can be assigned to four components, which are carbide (MoC1-x), MoO2, oxycarbide (MoOxCy) and MoO3 at 228.6, 229.2, 230.1, 232.7 eV respectively22,39. C 1 s XPS spectra (b) can be deconvoluted into four components, which are carbide (MoC1-x), adventitious carbon contamination (C-C), C-O and C = O linkage at 283.4, 284.6, 286.4, and 288.3 eV respectively22,40. Au 4f7/2 XPS spectra (Fig. 2c) can be attributed to two components, which are Au0 with diameter larger than 3 nm and Auδ+ with diameter of 2 to 3 nm at 84.0 and 84.3 eV, respectively29,33,35.

Extended Data Fig. 6 Quasi in-situ XPS, DRIFT spectra and Pulse chemisorption of Au/α-MoC catalysts.

a, Quasi in-situ XPS of 6Au/α-MoC before (as-prepared) and after H2 reduction (30 ml min−1) at 300 °C, 0.1 MPa for 1 hour. The residual oxygen can be attributed to unreduced MoOx40,63. b, Comparison of in-situ DRIFT spectra for 15Au/α-MoC, 6Au/α-MoC, 1Au/α-MoC and α-MoC in CO (0.1 MPa) atmosphere. c, Competitive pulse chemisorption. The as-prepared (left) and H2-reduced (right) sample denote the catalyst before and after H2 reduction (300 °C,1 hour) followed by He purge (300 °C, 0.5 hour), respectively. Then the mixed gas of CO/C2H2/He (5/5/90, 0.1 MPa, 30 ml min−1) was pulsed through 10 mg of samples at 30 °C. d, TPD profiles of 6Au/α-MoC before and after H2 reduction at 300 °C for 1 hour. e, Schematic illustration for pulse chemisorption.

Extended Data Fig. 7 Kinetic measurements.

a,b, Kinetic isotope effect (KIE) of the CO-H2O-AHE reaction by replacing H2O or CO with D2O and 13CO, respectively. a, MS signals. b, Influence of KIE on the reaction rate determined by GC. Error bars represent the standard deviation from at least two independent measurements. c-f, Correlation between experimentally measured rC2H4 and simulated ones by assuming different rate-determining step (RDS) in the reaction model (See Supplementary Note 2).

Extended Data Fig. 8 Free energy profiles for oxygen adsorption and H2O dissociation on α-MoC(111) surface.

a, Differential adsorption energies of oxygen on α-MoC(111) surface referenced to O2 gas. b, Free energy profile for H2O dissociation to two OH* combining with a surface O* specie on the α-MoC(111) surface. c, Top and side views of the Au/α-MoC(111) model in Fig. 4d with 31 Au atoms on a 8 × 8 α-MoC slab. Cyan, grey, red and white spheres represent Mo, C, O and H atoms, respectively. d, The structures of the transition states in Fig. 4d.

Extended Data Fig. 9 DFT studies of the reactivity and selectivity.

a, Partial density of states (PDOS) for the C 2p in the adsorbed C2H4, O 2p in the adsorbed OH, and Mo 4d orbital of the corresponding adsorption sites labelled by dotted circles in the structure. b, Gibbs free paths for CH3CHO formation via Vinyl alcohol (CH2CHOH*) and CHCH3 intermediate. Gold, cyan, red, grey and white spheres represent Au, Mo, O, C and H atoms, respectively. c, Interaction energy between α-MoC and different metals. The interaction energy was calculated by (Esupported - EMoC – nμmetal)/m, in which Esupported and EMoC are the energies of the supported structure and the MoC support, respectively, and μmetal is the chemical potential of a metal atom in its bulk phase, n is the total number of metal atoms in the supported metal nanoparticle (that is 31), m is number of metal atoms bonding with the MoC surface (that is 19). The interaction energy implies the formation enthalpy of the interfacial structure, which reflects its relative thermodynamic stability.

Supplementary information

Supplementary Information

Supplementary Notes 1 and 2, Figs. 1 and 2, Tables 1–3 and references.

Supplementary Data 1

Vibrational frequencies of the transition states.

Supplementary Data 2

Optimized atomic structures of intermediate states.

Supplementary Data 3

Statistical source data for Supplementary Fig. 2.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Extended Data Fig. 1

Statistical source data.

Source Data Extended Data Fig. 2

Statistical source data.

Source Data Extended Data Fig. 3

Statistical source data.

Source Data Extended Data Fig. 5

Statistical source data.

Source Data Extended Data Fig. 6

Statistical source data.

Source Data Extended Data Fig. 7

Statistical source data.

Source Data Extended Data Fig. 8

Statistical source data.

Source Data Extended Data Fig. 9

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, R., Xia, M., Zhang, Y. et al. Acetylene hydrogenation to ethylene by water at low temperature on a Au/α-MoC catalyst. Nat Catal 6, 1005–1015 (2023). https://doi.org/10.1038/s41929-023-01026-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-023-01026-y

This article is cited by

-

Promoter Effect on Ni/SiO2 Catalysts for Acetylene Semi-hydrogenation to Ethylene

Catalysis Letters (2024)